Understanding the 10 kV Transformer

A10 kV transformeris a medium-voltage electrical device designed to step voltage up or down between theprimary level of 10 kilovolts (kV)and a secondary voltage suitable for distribution, typically 0.4 kV or 11 kV. These transformers are vital inpower transmission and distribution networks, serving as a bridge between high-voltage transmission systems and low-voltage consumer endpoints.

10 kV transformers are commonly manufactured inoil-immersedordry-typeformats, and they are widely used in utility substations, industrial plants, commercial buildings, and rural electrification systems. Their role is essential in ensuring safe, efficient, and continuous power delivery.

Applications of a 10 kV Transformer

These transformers are widely deployed across sectors, including:

- Utility Substations: For voltage regulation between primary transmission and secondary distribution.

- Industrial Facilities: Powering machinery, motors, and process equipment requiring medium voltage.

- Residential Communities: Step-down transformation for household distribution in suburban and rural grids.

- Renewable Energy: Connecting solar farms or wind turbines to local distribution networks.

- Infrastructure Projects: Used in railways, airports, and water treatment plants for stable power management.

Market Background and Industry Trends

The global demand for medium-voltage transformers is growing due to increased investments in energy infrastructure, urbanization, and the transition to renewable energy. According toIEEMAand reports fromMarketsandMarkets, the medium-voltage transformer market is expected to surpassUSD 15 billion by 2030, with 10 kV units playing a central role in secondary substation deployments.

IEEE articles andWikipedia’sTransformer guideentryhighlight the growing adoption of compact, energy-efficient 10 kV transformers as utilities modernize their grids to reduce transmission losses and improve reliability.

Technical Specifications of a Typical 10 kV Transformer

Key specifications vary by manufacturer and use case but generally include:

- Rated Capacity: 100 kVA – 2500 kVA

- Primary Voltage: 10 kV (±5% or ±2×2.5% tap range)

- Secondary Voltage: 400 V / 11 kV (customizable)

- Frequency: 50 Hz / 60 Hz

- Cooling Type: ONAN (Oil Natural Air Natural) or AN/AF for dry-type

- Connection Method: Dyn11 / Yyn0 / Yd11

- Insulation Class: A (oil-type), F or H (dry-type)

- No-load Loss: ~0.2% of rated power

- Impedance Voltage: 4% – 6%

- Protection Level: IP00 (dry) or IP23/IP44 (enclosure)

- Installation Environment: Indoor or outdoor (with weatherproof housing)

Comparison with Other Medium Voltage Transformers

| Feature | 10 kV Transformer | 11 kV Transformer | 6.6 kV Transformer |

|---|---|---|---|

| Standard Primary Voltage | 10,000 V | 11,000 V | 6,600 V |

| Common in | China, Central Asia | India, UK, South Africa | Japan, select industries |

| Application Focus | Secondary substations | Distribution substations | Industrial applications |

| Design Similarities | Oil/Dry, Dyn11/Yyn0 | Nearly identical | May require higher insulation design |

The 10 kV transformer differs from the more commonly referenced 11 kV units mainly byregional voltage standards, especially inChina and parts of Central Asiawhere 10 kV networks are predominant.

Selection Guide: How to Choose the Right 10 kV Transformer

Choosing the ideal 10 kV transformer requires evaluating the following:

- Load Profile

Calculate your maximum and average power load (in kVA). Choose a transformer with at least 20% headroom for safety. - Installation Environment

- Useoil-immersed transformersfor outdoor, high-capacity needs.

- Choosedry-type transformersfor indoor use, especially in fire-sensitive environments like hospitals or commercial buildings.

- Efficiency Requirements

Look for units withlow no-load and load losses, compliant withIEC 60076 efficiency standards. - Regulatory Compliance

Ensure certification byCE,UL, orGB/Tstandards based on your region. - Protection and Monitoring

- Overload protection (relays or fuses)

- Temperature sensors (especially for dry types)

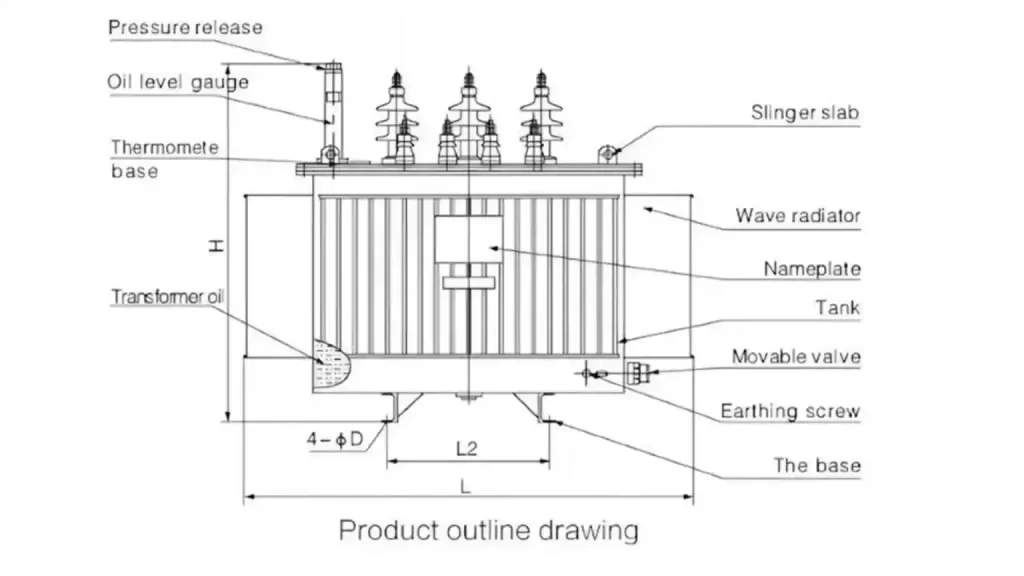

- Buchholz relay and oil level gauge (for oil-filled models)

Leading manufacturers such asSchneider Electric,ABB, andSiemensprovide customizable 10 kV transformer models with a range of advanced features.

Best Practices and Recommendations

- For safety, all transformers should be grounded properly and installed with surge arresters.

- Periodic oil testing (for oil-immersed types) ensures insulation integrity and cooling performance.

- Use cable termination kits certified for 10 kV voltage class to prevent corona discharge or tracking.

IEEE guides on transformer maintenance recommend annual inspection intervals and infrared thermography for early fault detection.

Frequently Asked Questions (FAQ)

A: The main difference lies in thenominal voltage rating—10 kV is used in certain countries like China, while 11 kV is standard in India, the UK, and others. Electrical characteristics and applications are otherwise very similar.

A: It depends. Some systems allow for minor tolerance in voltage (±5%), but using a 10 kV transformer in an 11 kV grid may require tap adjustments or insulation re-evaluation.

A: With proper maintenance, a 10 kV transformer can last25 to 35 years. Factors like load variation, environmental conditions, and insulation quality all impact lifespan.

The10 kV transformeris a trusted workhorse in medium-voltage distribution networks, offering dependable voltage regulation, high efficiency, and adaptability across industries. With a variety of configurations and models available, these transformers are essential to modern energy infrastructure.

Professionals seeking reliable performance, long service life, and compliance with international standards should consider 10 kV transformers from reputed manufacturers such asABB,Schneider Electric, andSiemens. For technical selection, referencing guidelines fromIEEEandIEEMAensures safe and optimized deployment.