- Introduction to 220/33 kV Power Transformer

- Standard Electrical Specifications

- Construction Features

- 1. Core

- 2. Windings

- 3. Tank & Conservator

- 4. Bushing and Terminals

- 5. Cooling System

- Dimensional Specifications

- Protection and Monitoring

- Cooling Methods Explained

- Accessories and Optional Features

- Installation Considerations

- Applications of 220/33 kV Transformers

- Why Choose PINEELE?

- Frequently Asked Questions (FAQs)

Introduction to 220/33 kV Power Transformer

A220/33 kV transformeris a high-voltage step-down power transformer used in transmission substations to reduce voltage from 220 kV to 33 kV for further distribution. Thesetransformersare critical in grid substations, industrial plants, and renewable energy interconnection facilities.

At PINEELE, we design and manufacture advanced220/33 kV powertransformers guidewith high efficiency, superior insulation, and compliance with IEC, ANSI, and GB standards.

Standard Electrical Specifications

| Parameter | Typical Value / Description |

|---|---|

| Rated Power | 25 MVA, 31.5 MVA, 40 MVA, 63 MVA, etc. |

| Primary Voltage | 220 kV |

| Secondary Voltage | 33 kV |

| Frequency | 50 Hz or 60 Hz |

| Number of Phases | 3-phase |

| Vector Group | YNd11 / YNyn0 / YNd1 |

| Tap Changer | OLTC ±10% in 16 steps or OCTC ±5% |

| Insulation Class (HV/LV) | A/B/F/H (depends on design) |

| Cooling Type | ONAN / ONAF / OFAF / OFWF |

| Impedance | 8–12% (based on capacity & design) |

| Temperature Rise | 55°C / 65°C |

| Standard | IEC 60076 / ANSI C57 / GB 6451 |

Construction Features

1.Core

- Cold-rolled grain-oriented silicon steel

- Low loss, laminated and clamped

2.Windings

- Copper conductor (Paper or Nomex insulated)

- Helical or disc type winding

- LV: layer windings; HV: disc windings

3.Tank & Conservator

- Hermetically sealed or conservator tank

- Mild steel or stainless steel

- Radiator panels or external oil coolers

4.Bushing and Terminals

- Porcelain or polymer bushings

- HV: 220 kV class; LV: 36–40.5 kV class

5.Cooling System

- ONAN for natural cooling

- ONAF or OFAF for higher loads with fans or pumps

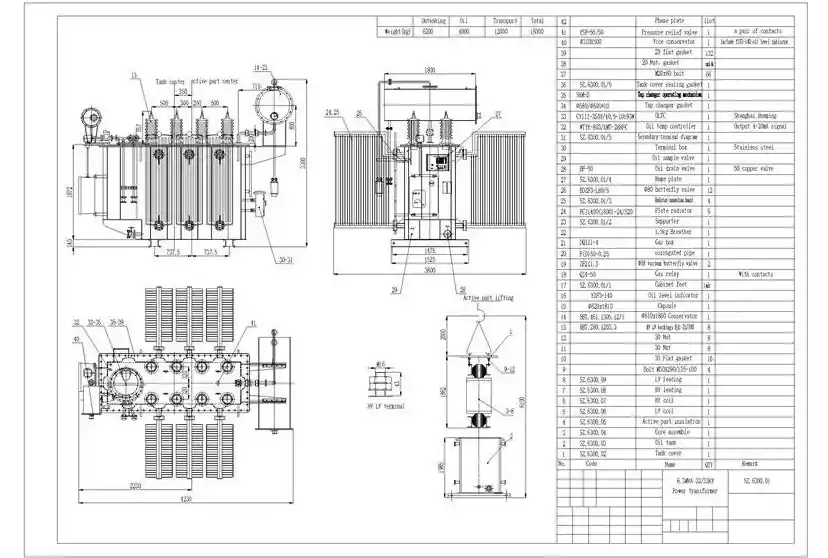

Dimensional Specifications

| Capacity (MVA) | L x W x H (m) | Weight (tons) |

| 25 MVA | 4.2 x 2.6 x 3.4 | ~28 tons |

| 31.5 MVA | 4.5 x 2.8 x 3.6 | ~32 tons |

| 40 MVA | 4.8 x 3.0 x 3.8 | ~36 tons |

| 63 MVA | 5.2 x 3.2 x 4.0 | ~45 tons |

Dimensions vary by cooling type and protection accessories.

Protection and Monitoring

- Buchholz Relay (Gas detection)

- WTI / OTI (Winding & Oil Temp Indicators)

- PRD (Pressure Relief Device)

- Oil Level Indicator (Magnetic or float type)

- On-load Tap Changer Controller (OLTC motor drive)

- Bushing CTs and LV metering

- Digital Monitoring (optional IoT sensors, SCADA compatible)

Cooling Methods Explained

| Cooling Type | Description | Applications |

| ONAN | Oil Natural Air Natural | Up to 31.5 MVA |

| ONAF | Oil Natural Air Forced (fans) | 31.5–63 MVA |

| OFAF | Oil Forced Air Forced (fans & pumps) | Large stations or peak loads |

| OFWF | Oil Forced Water Forced | High-capacity industrial use |

Accessories and Optional Features

- Radiators (bolt-on or corrugated)

- Oil filtration valves

- Drain valve with sampling point

- Nitrogen injection system (optional)

- OLTC panel with local/remote operation

- Arcing horns, disconnecting links

- Smart transformer integration (IoT-ready)

Installation Considerations

- Foundation pad based on weight and seismic load

- HV and LV cable trench alignment

- Minimum clearance: 3.5m HV side, 2.5m LV side

- Earthing system design (< 1Ω resistance target)

- Oil containment pit for environmental safety

Applications of 220/33 kV Transformers

- Transmission & Distribution (T&D) substations

- Renewable energy step-down systems (wind, solar farms)

- Large industrial power networks

- Utility grid substations

- Smart city infrastructure

Why Choose PINEELE?

PINEELE is a trusted supplier ofhigh-voltage transformerswith:

- In-house design and testing labs

- Compliance with IEC, GB, and ANSI standards

- Short lead time and global logistics

- SCADA and IoT-ready smart options

- Customized designs up to 100 MVA / 220 kV

📧 Email:[email protected]

📞 Phone: +86-18968823915

💬 WhatsAppSupport Available

Frequently Asked Questions (FAQs)

A:For a 40 MVA unit, oil volume is typically 6,000–9,000 liters, depending on the cooling system.

A:Standard lead time is 10–16 weeks, depending on custom features and testing requirements.

A:Yes, PINEELE offers solar-compatible units with advanced protection and remote monitoring.

The220/33 kV power transformeris a cornerstone in modern power infrastructure, serving as the vital link between high-voltage solutionstransmission and medium-voltage distribution. With advanced insulation, protection, and smart integration options, PINEELE transformers ensure reliable, efficient, and future-ready power conversion.

“Empowering Grids, Enabling Growth — Engineered by PINEELE.”