European Standard Compact Substation

TheEuropean Standard Compact Substationis afully integrated, space-efficientpower distribution solution designed to meetEuropean safety and performance standards. It combinesmedium-voltage (MV) switchgear, a distribution transformer, and low-voltage (LV) switchgearwithin a single, weatherproof enclosure, ensuringreliability, efficiency, and safetyfor industrial, commercial, and urban applications.

Unlike conventional substations, thiscompact modular unitreduces installation space while providingseamless power distribution, lower transmission losses, and enhanced energy efficiency. Compliant withIEC 62271-202, it offersrobust electrical protection and high operational reliability.

Key Features:

- Compact, fully enclosed design– Enhances safety and reduces maintenance.

- Quick installation– Factory-assembled for easy deployment.

- Advanced protection & monitoring– Ensures system reliability.

- Energy-efficient– Minimizes transmission losses and improves power quality.

- Customizable configurations– Available in various voltage and power ratings.

- Durable & weatherproof– Suitable for indoor and outdoor environments.

Widely used inrenewable energy plants, construction sites, mining, data centers, and railway electrification, theEuropean Standard Compact Substationis theideal choicefor modern power distribution, offeringhigh performance, safety, and efficiency.

Product Overview

- The foundation must have a bearing capacity of at least1000 Pa.

- The foundation should be built on relatively high ground, with external drainage on all sides. Use200# cement mortarmixed with 3% waterproofing agent, and ensure the bottom slopes slightly towards the oil tank (the oil tank is removed when installing a dry-type transformer).

- The foundation construction should comply withJGJ1683 "Technical Specification for Architectural Power Design"and relevant regulations.

- Grounding electrodes should be installed according to standard specifications, with a grounding resistance ≤4 ohms.

- Ambient air temperature:Maximum40°C, Minimum-25°C.

- Altitude:≤1000 W/m²(For altitudes exceeding100m, consult for special order details).

- Wind speed:≤35m/s.

- Seismic intensity:≤Level 8.

- Ice thickness:≤20mm.

- Humidity:

- Daily average relative humidity ≤95%; Monthly average relative humidity ≤90%.

- Daily average water vapor pressure ≤2.2kPa; Monthly average water vapor pressure ≤1.8kPa.

- The installation site should befree from flammable and explosive hazards, chemical corrosion, and severe vibrations.

Note:Forspecial environmental conditions, please specify requirements at the time of order so that the manufacturer can provide solutions accordingly.

What is the IEC standard for compact substation?

TheIEC standard for compact substationsis primarily defined underIEC 62271-202, which provides guidelines for prefabricated and factory-assembled medium voltage/low voltage (MV/LV) substations. This standard ensures that compact substations are designed, manufactured, and tested to meet the highest safety, reliability, and operational efficiency requirements.

IEC 62271-202 covers thetechnical requirements, safety considerations, environmental performance, and testing methodsforcompact secondary substations (CSS)used inpower distribution networks up to 52 kV. The standard applies to fully enclosed substations that integrateMV switchgear, a transformer, and LV switchgearwithin a single, prefabricated enclosure.

Key Requirements of IEC 62271-202 for Compact Substations

- Structural Integrity:The enclosure must be designed to withstand mechanical, electrical, and environmental stresses.

- Internal Arc Protection:The standard defines IAC classifications (e.g.,IAC-A, IAC-B, IAC-AB) to protect personnel in case of internal arc faults.

- IP Ratings:Specifies the required level of protection against dust and water ingress (e.g.,IP54, IP65).

- Dielectric Strength:Ensures insulation withstands high-voltage stress without breakdown.

- Thermal Stability:Compact substations must dissipate heat efficiently to prevent transformer overheating.

- Short-Circuit Withstand Capability:The MV switchgear and other components must be tested for fault conditions.

- Protection and Control Systems:Requirements for built-inrelays, fuses, and circuit breakersto enhance operational safety.

- Environmental Considerations:The substation must be resistant to corrosion, UV radiation, and extreme weather conditions.

Importance of IEC Compliance in Compact Substations

Compliance withIEC 62271-202ensures that compact substations meetglobal safety and performance benchmarks. This is particularly important forutility companies, industrial facilities, renewable energy plants, and urban power distribution networksthat require high-reliability solutions. IEC-certified compact substations reduce the risk ofelectrical failures, improve operational efficiency, and enhance system longevity.

Furthermore, the standard supportssmart grid integration, enabling modern compact substations to includeremote monitoring, automated fault detection, and energy efficiency enhancements. Many leading manufacturers of compact substations design their products tonot only comply with IEC 62271-202 but also with regional safety regulations such as ANSI, GB, and EN standards.

TheIEC 62271-202 standardplays a critical role in defining thedesign, testing, and operational requirementsfor compact substations worldwide. By ensuring compliance with this standard, manufacturers and power utility providers can guaranteesafety, reliability, and long-term performancein various applications. Whether used inindustrial zones, urban infrastructure, data centers, or renewable energy projects, IEC-certified compact substations provide an essential solution for modern power distribution needs.

European Standard Compact Substation Parameters

| Product Technical Parameters | ||||

|---|---|---|---|---|

| Product Name | Unit | High Voltage Electrical Equipment | High Voltage Electrical Equipment | Low Voltage Electrical Equipment |

| Rated Voltage | kV | 10 | 10 | 0.4 |

| Rated Current | A | 630 | 630 | 100~2500 |

| Rated Frequency | Hz | 50 | 50 | 50 |

| Rated Capacity | kVA | |||

| Rated Thermal Stability Current | kA | 20/4S | 20/4S | 30/15 |

| Rated Dynamic Stability Current (Peak) | kA | 50 | 50 | 63 |

| Rated Closing Short-Circuit Current (Peak) | kA | 50 | 50 | 15~30 |

| Rated Breaking Short-Circuit Current | kA | 31.5 (Fuse) | 31.5 (Fuse) | |

| Rated Load Breaking Current | A | 630 | 630 | |

| 1min Power Frequency Withstand Voltage | kV | To Ground, Phase-to-Phase 42, Interruption 48 | To Ground, Phase-to-Phase 42, Interruption 48 | 20/2.5 |

| Lightning Impulse Withstand Voltage | kV | To Ground, Phase-to-Phase 75, Interruption 85 | To Ground, Phase-to-Phase 75, Interruption 85 | |

| Enclosure Protection Level | IP23 | IP23 | IP23 | |

| Noise Level | dB | |||

| Number of Circuits | 1~6 | 1~6 | 4~30 | |

| Maximum Reactive Power Compensation on Low Voltage Side | kvar | 300 | ||

Product Overview

European compact substations are suitable for urban ring network power supply, dual power supply, or terminal power supply systems. They serve as high-voltage metering, compensation control, and protection devices. The high-voltage side is equipped with four-position load switches, backup fuses, and plug-in fuses. The low-voltage side is configured with control devices, distribution devices, compensation devices, and energy metering units according to user requirements.

Compact substations can be used both indoors and outdoors, widely applied in industrial parks, commercial centers, multi-story buildings, and various other environments.

Product Features

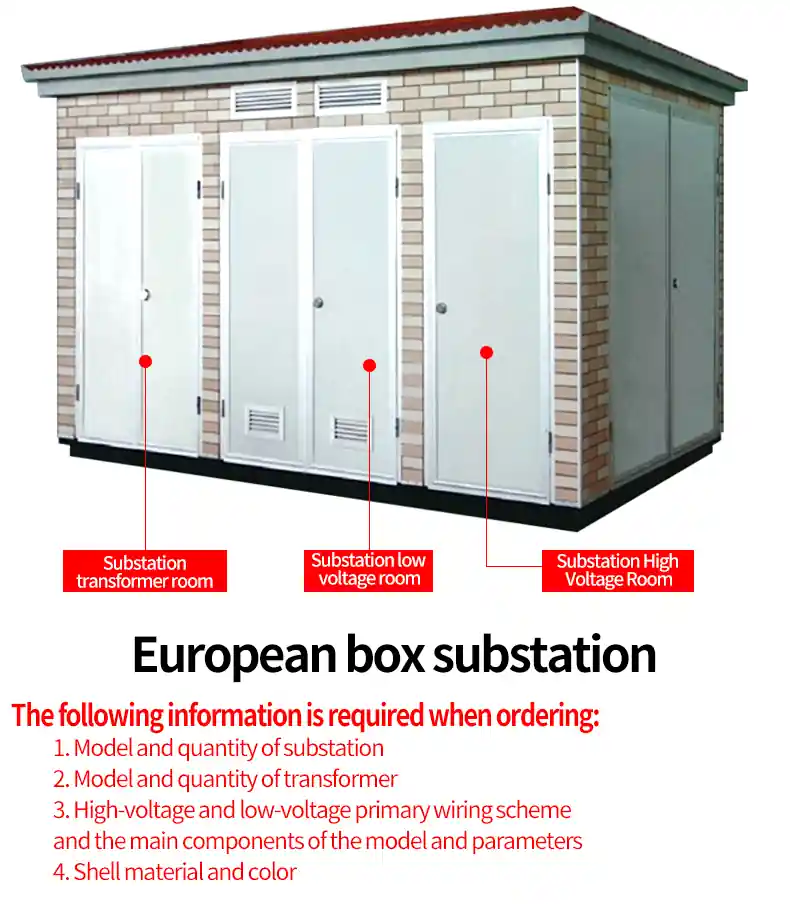

Compact substations integrate high-voltage distribution devices, transformers, and low-voltage distribution equipment into a single unit, forming three functional compartments:high-voltage chamber, transformer chamber, and low-voltage chamber. These chambers provide a complete power supply system that supports ring network power supply, terminal power supply, and dual power supply configurations to meet different power distribution needs. Additionally, high-voltage metering units can be installed to fulfill the requirements of high-voltage energy measurement.

The transformer options includeS9/S11/S13/SCB10series, as well as dry-type or oil-immersed transformers. The low-voltage chamber can be customized using panel or cabinet-type structures according to user requirements, offering various functional solutions such as automatic distribution, lighting distribution, power factor compensation, energy metering, and electrical parameter measurement to meet diverse application needs. These features facilitate efficient power management and improve power supply quality.

The high-voltage chamber adopts a compact design and features acomprehensive interlocking systemto prevent operational errors. When required, the transformer chamber can be accessed easily through wide openings, ensuring convenient equipment installation and maintenance. Each compartment is equipped withautomatic lighting devices, while all components in the high and low-voltage chambers usefully enclosed equipmentfor enhanced safety and reliability.

Ventilation is achieved through a combination ofnatural ventilation and forced ventilation. The transformer, high-voltage, and low-voltage chambers are all equipped with ventilation systems, andtemperature control units automatically activate and deactivate exhaust fansbased on preset temperature thresholds, ensuring stable transformer operation.