- 1. Product Overview

- 2. Compliance Standards

- Key Technical Parameters

- 3. Key Features

- 3.1 High Safety and Reliability

- 3.2 Modular and Scalable Design

- 3.3 Intelligent Control System

- 3.4 Robust Drawer Unit Design

- 4. Installation and Usage Guidelines

- 4.1 Pre-Installation Checklist

- 4.2 Installation Guidelines

- 5. Applications

- 6. Conclusion

1. Product Overview

TheGCK Low-VoltageWithdrawable Switchgearis a state-of-the-artdistribusi dayasystem widely used inpower plants, metallurgical steel rolling, petrochemical industries, light industry, ports, buildings, and hotels. It is designed forAC three-phase four-wire or five-wire systems, operating at voltages of 380V and 660V, with a frequency of 50Hz, and a rated current of up to 5000A.

Iniswitchgearcomplies withnational and international standards, undergoingcomprehensive type testing and CCC certificationmemastikanhigh safety, reliability, and modular design flexibility.

2. Compliance Standards

The GCK switchgear meets the following standards:

✔GB 7251.1-2005– Low-voltage switchgear (National Standard)

✔IEC 60439.1-1992– Low-voltage switchgear and controlgear (International Standard)

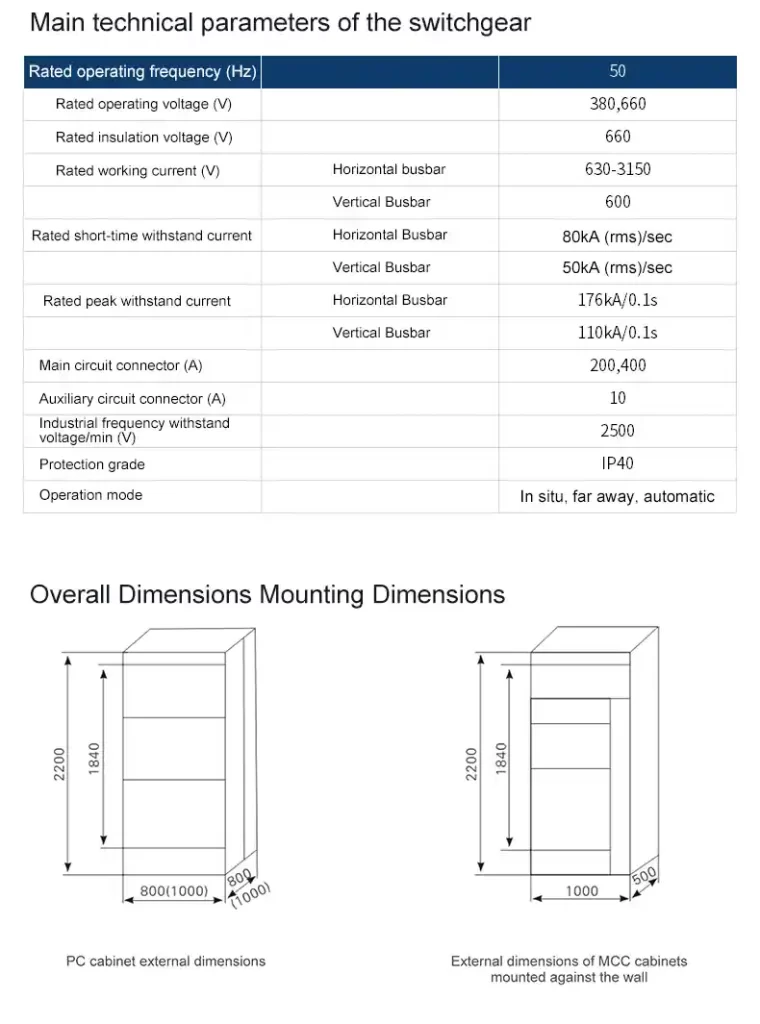

Key Technical Parameters

| Spesifikasi | Value |

|---|---|

| Tegangan Isolasi Terukur | 660V / 1000V |

| Rated Operating Voltage | 400V / 660V |

| Tegangan Sirkuit Tambahan | AC 380V / 220V, DC 110V / 220V |

| Busbar Rated Current | 1000A – 5000A |

| Short-Time Withstand Current (1s) | 50kA, 80kA |

| Peak Withstand Current | 105kA, 140kA, 176kA |

| Branch Busbar Rated Current | 630A – 1600A |

| Tingkat Perlindungan | IP30, IP40 |

| Sistem Busbar | Three-phase four-wire / five-wire |

| Operation Mode | Local, Remote, Automatic |

3. Key Features

3.1 High Safety and Reliability

Independent compartmentalization: The cabinet is divided into abusbar room, functional unit room, and cable room, preventing the spread of electrical faults.

Advanced short-circuit withstand capacity, with busbars designed to handleup to 176kA peak current.

3.2 Modular and Scalable Design

Customizable configurationsfor power distribution and motor control applications.

EachMotor Control Center (MCC) cabinetcan accommodateup to 9 1-unit drawers or 18 1/2-unit drawers.

3.3 Intelligent Control System

Supportsmanual, remote, and automatic operation, enabling seamless integration intosmart power distribution networks.

3.4 Robust Drawer Unit Design

Drawer locking mechanismprevents accidental withdrawal when the main switch is closed.

Rotary propulsion systemensures smooth drawer operation withthree-position interlocking(Connected, Test, Isolated).

Main circuit plug-in and auxiliary circuit plug-infor easy maintenance.

4. Installation and Usage Guidelines

4.1 Pre-Installation Checklist

Inspect packaging integrity and verify all accessories.

Store units in a dry, ventilated environment before installation.

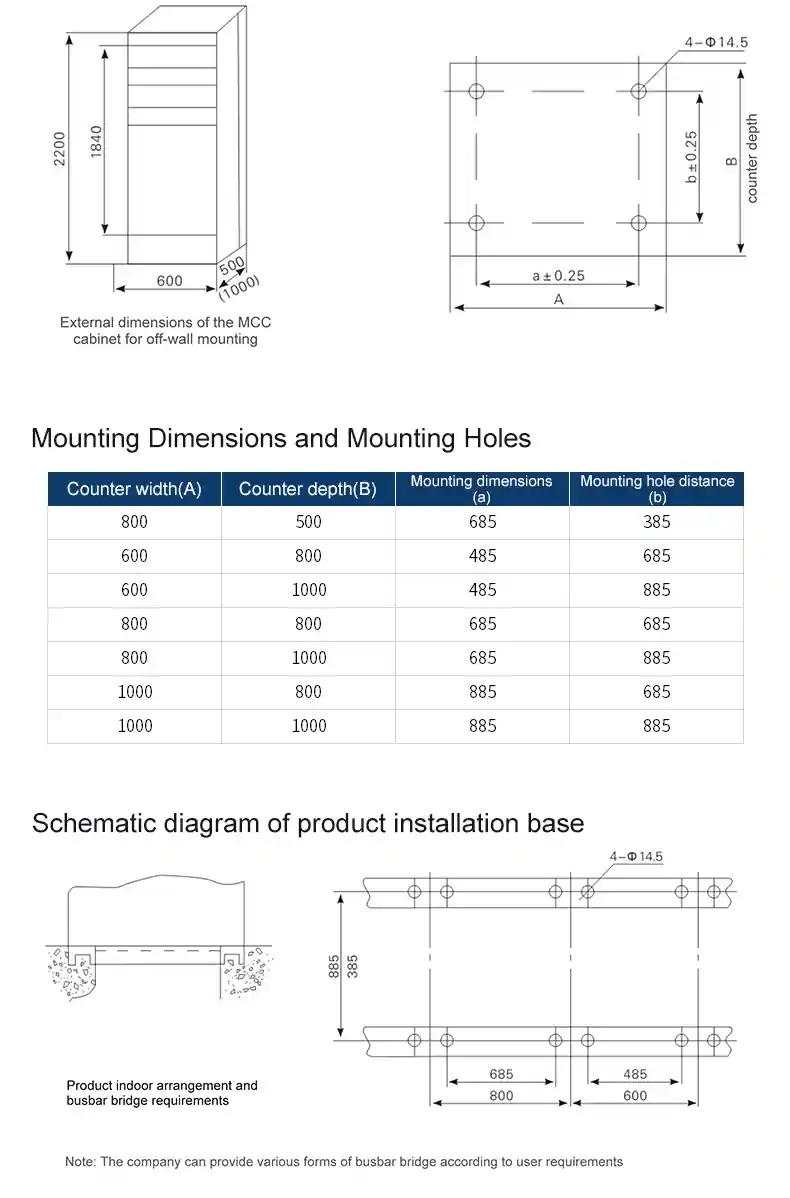

4.2 Installation Guidelines

Follow the providedinstallation schematics and diagrams.

Ensureproper grounding and cable routingto prevent operational hazards.

Leave sufficient clearance forventilation and maintenance.

5. Applications

TheGCK switchgearis widely applied in various industries, including:

✔Power plants, substations, and industrial automation systems

✔Steel, chemical, and petrochemical industries

✔Commercial buildings, airports, and large infrastructure projects

✔Renewable energy projects (solar and wind power integration)

Due to itshigh adaptability,modular design guide, and advanced safety features, the GCK switchgear is apreferred choice for modern power distribution and motor control systems.

6. Conclusion

TheSwitchgear yang Dapat Ditarik Tegangan Rendah GCKdeliversexceptional reliability, flexibility, and safetyinlow-voltage power distribution applications. With itsmodular design, advanced safety mechanisms, and compliance with international standards, sangat ideal untukhigh-performance industrial and commercial power systems.

📩Contact Us: [email protected]

📞Phone Consultation:+86-18968823915