Introduction to Vacuum Breakers A vacuum breaker is an essential type of circuit breaker that interrupts current flow in high-voltage electrical systems using vacuum as the arc-extinguishing medium. Unlike air or gas-insulated alternatives, a vacuum interrupter extinguishes the arc in a near-perfect vacuum environment, making it highly efficient, reliable, and safe for medium-voltage applications.

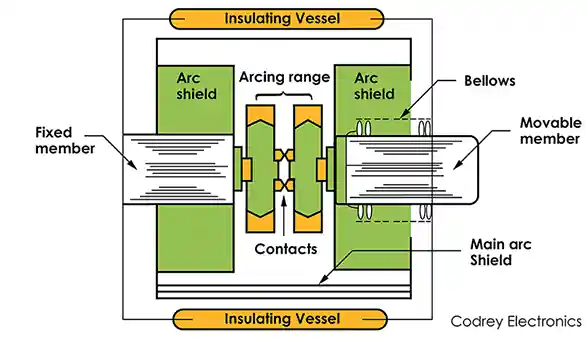

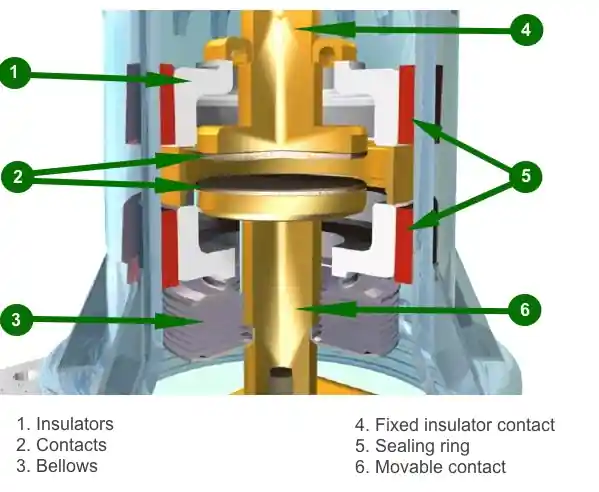

How Vacuum Breakers Work The core mechanism of a vacuum breaker lies in its vacuum interrupter chamber. Here’s how it functions:

- Contact Separation: When a fault is detected, the breaker mechanism forces the contacts apart inside a sealed vacuum chamber.

- Arc Formation: As the contacts separate, an arc forms due to ionization of metal vapors.

- Arc Extinction: In the vacuum, there are no gas molecules to sustain the arc. The arc is rapidly extinguished, usually within half a cycle of the AC waveform.

- Dielectric Recovery: The vacuum allows for very fast dielectric recovery, making the system ready for operation quickly.

Applications of Vacuum Breakers Vacuum circuit breakers are typically used in:

- Medium-voltage switchgear (1 kV to 38 kV)

- Power distribution systems in industrial plants

- Substations in utility grids

- Mining and marine applications

- Renewable energy systems

Their compact size, minimal maintenance, and long life make them ideal for mission-critical operations.

breaker guide installed in industrial switchgear panel” class=”wp-image-1284″/>

breaker guide installed in industrial switchgear panel” class=”wp-image-1284″/>Market Trends and Industry Adoption Nach Angaben von IEEE und IEEMA, vacuum breaker technology has become the dominant standard for medium-voltage systems worldwide. The market is seeing:

- Increased demand from smart grid expansion

- Rising installation in renewable energy plants

- Replacement of aging SF6-based breakers for environmental compliance

Manufacturers like ABB, Schneider Electricund Siemens have continued to innovate in contact material, actuator design, and digital integration.

Technical Parameters and Comparison

| Merkmal | Vacuum Breaker | SF6 Breaker |

|---|---|---|

| Arc Quenching Medium | Vacuum | Sulfur Hexafluoride (SF6) |

| Dielectric Recovery Time | Very Fast | Moderate |

| Environmental Impact | None | High (greenhouse gas) |

| Maintenance Requirements | Low | Moderate to High |

| Typical Application Voltage | 1 kV to 38 kV | 72.5 kV and above |

Advantages Over Traditional Breakers

- No gas refilling required

- Long mechanical life (~10,000 operations or more)

- Fast arc extinction and low energy loss

- Compact and modular design

These benefits have made vacuum breakers increasingly preferred in urban and industrial electrical networks.

Buying Guide and Selection Tips When selecting a vacuum breaker:

- Match voltage and current rating to your system

- Choose between fixed or withdrawable types depending on maintenance needs

- Prefer models with digital diagnostics for smart grid compatibility

- Ensure compliance with IEC 62271 or ANSI/IEEE C37.04 standards

FAQ Section

A vacuum provides excellent insulation and arc-extinction capability without introducing harmful gases, making the breaker more eco-friendly and efficient.

Generally, vacuum breakers are used in medium-voltage systems. For higher voltages, SF6 or air-insulated breakers are more common.

They require minimal maintenance, often after 10,000 operations or more, making them ideal for demanding environments.