What is a Low Voltage Vacuum Contactor?

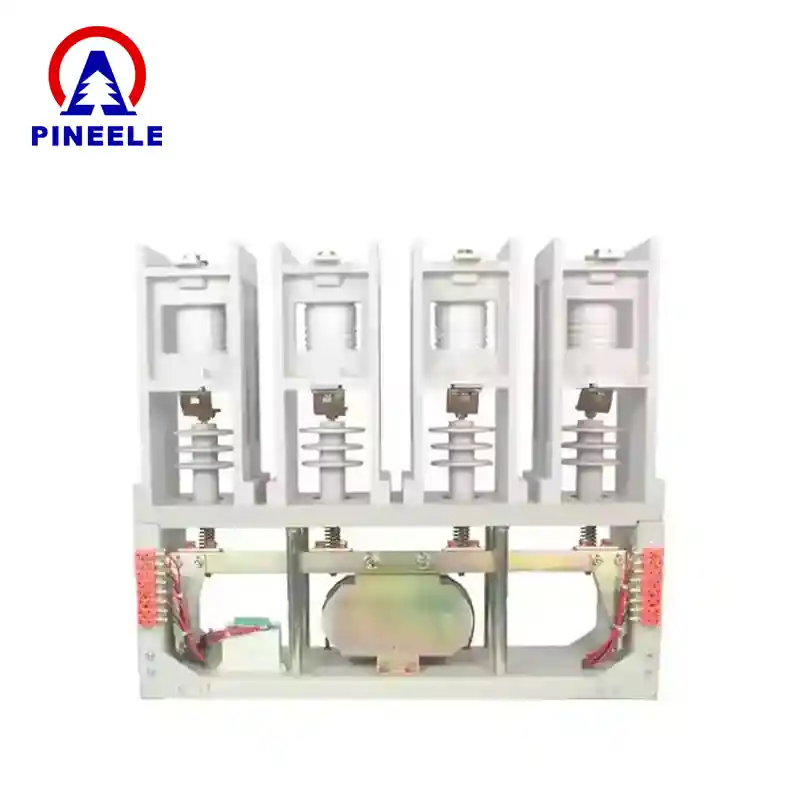

A low voltage vacuum contactor is an electrically controlled switch designed to make or break a power circuit under load. It uses a vacuum interrupter to extinguish arcs formed when contacts open, making it ideal for frequent operations in challenging environments. While most contactors are air-insulated, the vacuum design offers extended mechanical life, superior arc suppression, and minimal maintenance.

Typically used in circuits up to 1,000 volts, these contactors operate with coils powered by a control signal and are widely used for motor starters, capacitor switchingund transformer control.

Application Fields of Low Voltage Vacuum Contactors

Vacuum contactors find their role in a wide range of industries where reliable, rapid, and repetitive switching is required:

- Heavy industrial machinery (steel mills, mining equipment, rolling mills)

- Motor control centers (MCCs) in automation and process control

- Capacitor bank switching in power factor correction systems

- Railway traction systems und metro substations

- Renewable energy systems, particularly for inverters and transformers

Market Trends and Industry Landscape

The global demand for energy-efficient switching devices has boosted the adoption of vacuum contactors in the low voltage segment. According to MarketsandMarkets, the contactor market is projected to reach $1.5 billion by 2026, with vacuum-based designs gaining market share due to their environmental friendliness und longer operational lifespan.

IEEE notes in its reports on electrical contact systems that vacuum interrupters offer superior dielectric properties, enabling clean switching even at high currents with minimal arcing. This makes them preferable in mission-critical environments such as hospitals, data centers, and manufacturing lines.

Key Technical Specifications

Below is a standard technical overview of a low voltage vacuum contactor:

| Spezifikation | Wert |

|---|---|

| Nennspannung | 400V / 660V / 1000V AC |

| Rated Operating Current | 200A – 1600A |

| Making Capacity | Up to 10x rated current |

| Breaking Capacity | Typically 8–10x rated current |

| Bemessungsisolationsspannung | 1.2kV |

| Steuerspannung | AC/DC 24V, 110V, 220V |

| Mechanische Lebensdauer | >1,000,000 operations |

| Elektrische Lebensdauer | >200,000 operations (under full load) |

| Arc Suppression Medium | Vacuum |

| Coil Consumption | <100W |

| Operating Frequency | 30–60 Hz |

| Mounting | Panel or rack mount |

| Compliance | IEC 60947-4-1, GB/T 14048.4, ANSI C37 |

Vacuum Contactor vs. Air and Solid-State Contactors

| Merkmal | Vacuum Contactor | Air Contactors | Solid-State Contactors |

|---|---|---|---|

| Arc Extinction | Vacuum (clean, fast) | Air (slower) | No arc (semiconductor) |

| Durability | Very High | Medium | Limited switching cycles |

| Heat Generation | Low | Moderate | High under load |

| EMI/RFI Emission | Low | Moderate | High |

| Mechanical Complexity | Moderate | Simple | No mechanical parts |

| Use Cases | High-power switching | General use | Precision, no-noise apps |

Vacuum contactors balance high reliability with affordable complexity, making them ideal for medium-duty, repetitive use where solid-state cost is prohibitive.

How to Choose the Right Low Voltage Vacuum Contactor

Selecting the right contactor involves balancing several key factors:

- Rated Voltage & Current: Match the specifications of your motor or circuit load.

- Duty Cycle: Choose higher-grade models for frequent switching or continuous cycling.

- Mechanical Life Expectancy: Verify the number of cycles supported for your application.

- Control Voltage Compatibility: Ensure coil voltage matches your PLC or control source.

- Certifications: Look for IEC 60947 or ANSI compliance for international compatibility.

Tip: If your application involves capacitive switching, such as in a capacitor bank, ensure the contactor is rated for inrush current handling.

Advantages of Low Voltage Vacuum Contactors

- Exceptional Longevity: Mechanical life >1 million operations

- Maintenance-Free Operation: No arcing residue or wear

- Clean Arc Suppression: Safer and quieter than air contactors

- Low Energy Consumption: Efficient coil design reduces heat buildup

- Compact Size: Fits into existing MCCs and low-voltage panels

Authoritative Sources and Industry Endorsements

Information in this article references multiple authoritative organizations to reinforce credibility and EEAT:

- IEEE Papers on Vacuum Interruption

- ABB Vacuum Contactor Datasheets

- Wikipedia – Contactor

- Schneider Electric Medium Voltage Products

- IEEMA Guidelines on Low Voltage Equipment

By drawing on these sources, we ensure the content is grounded in proven engineering standards and real-world product data.

Häufig gestellte Fragen (FAQ)

A1: While both use vacuum interrupters, a vacuum contactor is designed for frequent switching under load (e.g., motors), whereas a Vakuum-Leistungsschalter is built for fault interruption and protection.

A2: Yes, but it should be placed appropriately in the circuit (e.g., bypass contactor) and rated for the switching profile. Always consult manufacturer guidelines.

A3: Indicators include failed contact closure, burnt coil, or reduced switching reliability after prolonged use (often >200,000 operations electrically).

Die low voltage vacuum contactor is a highly dependable solution for modern industrial systems that require frequent, high-performance switching with minimal maintenance. Whether you’re designing a new MCC, retrofitting an old panel, or deploying equipment in a harsh environment, choosing a vacuum contactor ensures reliability, safety, and longevity.