Transformers are indispensable components in modern electrical infrastructure, enabling safe and efficient voltage conversion across power transmission and distribution networks guide. Whether for utility-scale substations, industrial facilities, or residential complexes, understanding transformer pricing involves far more than just checking a catalog.

So, how much does a transformer guide really cost? The answer depends on several technical, geographical, and market-driven factors. This article breaks down transformer costs, types, influencing factors, and buying recommendations to help decision-makers plan their budgets wisely.

What Is a Transformer?

A transformer is an electromagnetic device that transfers electrical energy between two or more circuits through electromagnetic induction. Its primary function is to step up or step down voltage levels, ensuring compatibility between different parts of a power system.

Common transformer types include:

- Distribution Transformers – For local voltage regulation (e.g., 11kV/0.4kV)

- Power Transformers – For bulk power transfer (e.g., 132kV and above)

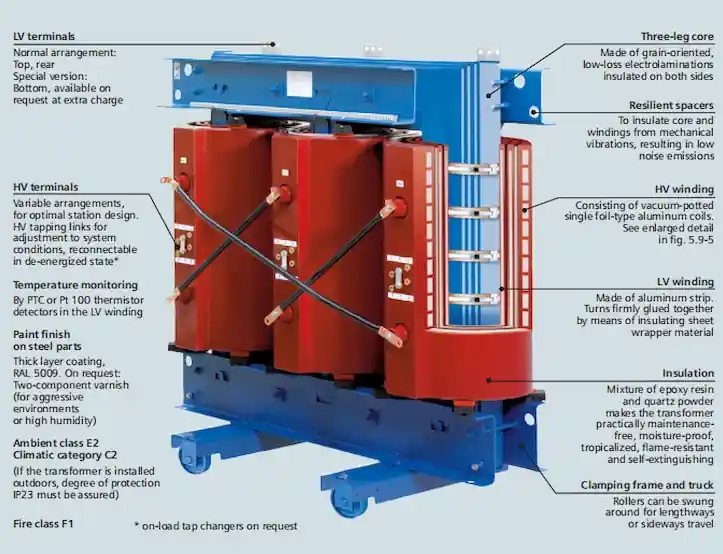

- Dry-Type Transformers – Used indoors or in fire-sensitive environments

- Pad-Mounted Transformers – For urban or underground applications

- Instrument Transformers – For metering and protection

Application Areas

Transformers are used in virtually every sector involving electricity:

- محطات المرافق الفرعية: Interconnect transmission and distribution networks

- Industrial Plants: Power heavy machinery, motors, and control systems

- Commercial Buildings: Provide localized voltage conversion for elevators, lighting, HVAC

- Renewable Energy Systems: Interface solar or wind output with the grid

- Oil & Gas: Operate pumps, rigs, and refineries with stable voltage supply

- Railway Electrification: Feed traction power at controlled voltage levels

Market Trends and Background

The global transformer market was valued at USD 60+ billion in 2023 and is projected to grow steadily due to increasing power demand, grid modernization, and renewable energy integration.

According to the International Energy Agency (IEA) و IEEMA, utility-scale transformer demand is expected to rise significantly in regions like India, Africa, and Southeast Asia due to ongoing rural electrification and smart grid projects.

IEEE standards such as C57.12.00 provide design and performance guidelines, ensuring interoperability and safety.

Transformer Price Range by Type and Capacity

Transformer prices can range from a few hundred to hundreds of thousands of USD, depending on size, type, and configuration.

| Transformer Type | Rating Range | Approx. Cost (USD) |

|---|---|---|

| Pole-Mounted Distribution | 25–250 kVA | $1,000 – $10,000 |

| Pad-Mounted | 75–2,500 kVA | $5,000 – $50,000 |

| Oil-Immersed Power | 5 MVA – 100 MVA | $30,000 – $500,000+ |

| Dry-Type Transformer | 50–3,000 kVA | $3,000 – $80,000 |

| Instrument CT/PT | Low burden class | $100 – $1,000 |

Note: These are average market estimates. Freight, customs, taxes, and local regulations can significantly impact final pricing.

Factors Affecting Transformer Cost

Understanding the key pricing drivers is essential for budgeting and procurement:

- Rated Capacity (kVA or MVA)

Higher capacity equals more copper, larger cores, and increased cost. - Voltage Class

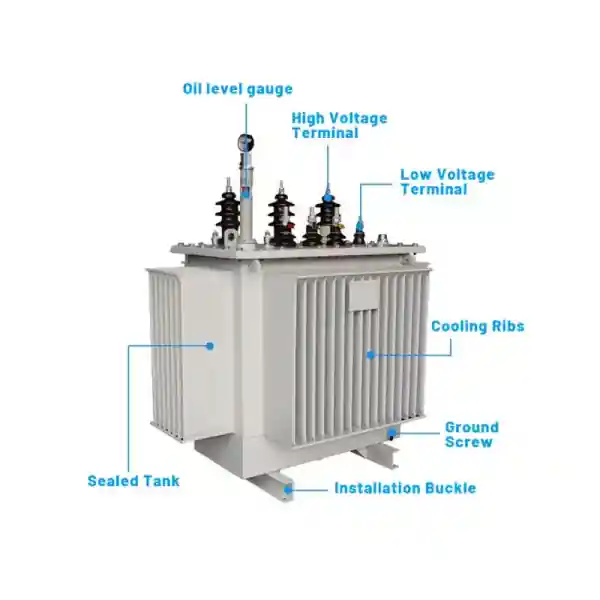

Transformers rated above 33kV require more insulation, larger bushings, and are significantly more expensive. - Type (Dry vs Oil-Immersed)

Dry-type transformers cost more per kVA but are preferred for indoor or fire-prone areas. - Efficiency Class

EcoDesign or DOE-compliant models cost more upfront but save money long-term. - Cooling Method

ONAN (oil natural air natural) is cheaper than ONAF (with forced cooling systems). - Customization

Special tap settings, enclosures (IP44/IP65), smart sensors, or arc-flash protection can increase the price. - Brand and Certification

Brands like ABB, شنايدر إلكتريكأو سيمنز often come with premium pricing due to global quality assurance. - Freight & Import Duties

International shipping, especially for oil-filled units, adds significant costs.

Cost Comparison: Dry-Type vs Oil-Immersed Transformers

| الميزة | Dry-Type Transformer | محول مغمور بالزيت |

|---|---|---|

| Fire Safety | High | Lower |

| Installation | Indoor or enclosed areas | Outdoor preferred |

| Maintenance | Minimal | Regular oil checks needed |

| Cost per kVA | Higher | Lower |

| Cooling | Air | Oil |

| Noise Level | Higher | Lower |

Each option suits different environments. For example, hospitals or malls prefer dry-types for safety, while power plants favor oil-immersed types for high efficiency and capacity.

Buying Advice and Selection Guide

When planning to purchase a transformer, consider the following steps:

- Load Profile Analysis: Match transformer size with maximum and average load.

- Site Environment: Choose dry-type for indoor use, oil-type for outdoor.

- Efficiency vs Cost Trade-Off: Look for Tier 2 or EcoDesign certified units if lifecycle cost matters.

- Vendor Reputation: Opt for certified manufacturers (ISO9001, IEC, IEEE-compliant).

- Lead Time: Custom transformers can take 6–12 weeks to manufacture.

- Spare Parts & After-Sales: Ensure availability of tap changers, bushings, or protection relays.

الأسئلة المتداولة (FAQ)

A: Pole-mounted oil-immersed distribution transformers (25–100 kVA) are generally the most cost-effective for rural or small-scale applications.

A: They use advanced epoxy or cast resin insulation, which is safer and maintenance-free, but more costly to produce.

A: Yes, used or refurbished units can reduce costs by up to 40%, but they must be thoroughly tested and certified by an authorized provider.

Conclusion

The cost of a transformer is influenced by a complex blend of technical parameters, application contextو market dynamics. Whether you are sourcing a 100 kVA distribution unit or a 50 MVA substation transformer, understanding the pricing framework helps ensure you get the right balance between performance, safety, and value.

Always consult with certified vendors and refer to international standards like those from معهد مهندسي الكهرباء والإلكترونيات IEEE, IEEMAو IEC when making a final decision. For long-term operational efficiency, total cost of ownership should take priority over the lowest initial price.