What is a Compact Substation?

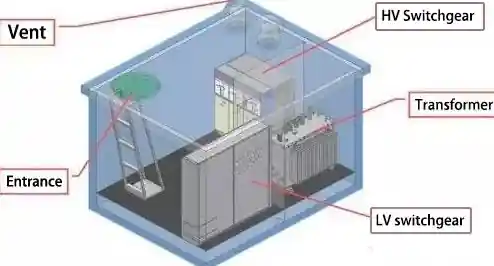

A compact substation, also known as a package substation or prefabricated substation, is an integrated solution that combines medium-voltage switchgear, transformer, and low-voltage switchgear within a single metallic enclosure. This design enables quick deployment in locations where space, safety, and environmental considerations are critical.

It is often used in urban distribution systems, renewable energy plants, construction sites, and industrial parks where conventional substations are impractical due to size or logistics.

Key Components of a Subestación compacta

Each compact substation is composed of the following core components:

1. Medium Voltage (MV) Switchgear

- Typically rated from 3.3 kV to 36 kV.

- Manages incoming MV power, isolating circuits and offering protection via vacuum circuit breakers (VCBs), load break switches (LBS), or SF6-insulated components.

- Standards: IEC 62271

2. Distribution Transformer

- Converts medium voltage to low voltage (e.g., 11kV/0.4kV or 33kV/0.4kV).

- Types include oil-immersed or dry-type transformers.

- Ratings usually range from 100 kVA to 2500 kVA.

3. Low Voltage (LV) Switchgear

- Distributes electricity to end users at 415V or 400V.

- Includes MCCBs, MCBs, contactors, meters, and surge arresters.

- Facilitates final protection and control of the power.

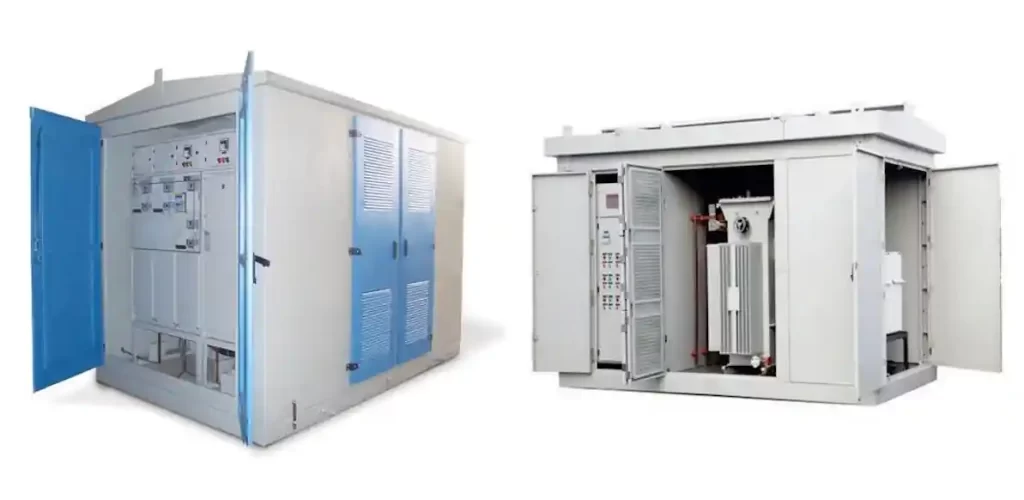

4. Enclosure or Housing

- Weatherproof, dust-proof, and corrosion-resistant, usually made from galvanized steel or aluminum.

- Designed with IP54 or higher protection class.

- Features include forced ventilation, anti-condensation heaters, and fire-resistant insulation.

5. Internal Wiring and Control

- Integrates protection relays, remote control devices, SCADA interfaces, and alarm systems.

Market Trends and Industry Background

As per IEEMA y IEEE studies, compact substations are gaining global traction due to increasing urbanization, expansion of renewable power projects, and digitization of grids. The International Energy Agency (IEA) reports that decentralized power networks are on the rise, particularly in Asia and Africa, where fast deployment and low land use are priorities.

Manufacturers like ABB, Siemensy Schneider Electric have noted growing demand for modular substations that support smart grid integration and reduced carbon footprints.

Technical Specifications at a Glance

| Component | Specification Range |

|---|---|

| Tensión nominal | 3.3 kV – 36 kV |

| Transformer Capacity | 100 kVA – 2500 kVA |

| Protection Class | IP54 – IP65 |

| Cooling Method | Natural air or oil-cooled |

| Enclosure Material | Galvanized steel / stainless steel |

| Standards Compliance | IEC 62271, IEC 60076, IEC 61439 |

| Temperature Range | -25°C to +50°C |

| Applications | Utility, renewable, industrial, commercial |

Comparison with Traditional Substations

| Feature | Subestación compacta | Traditional Substation |

|---|---|---|

| Footprint | Small | Large |

| Installation Time | Short (plug-and-play) | Long (civil work required) |

| Maintenance | Low | High |

| Safety | Enclosed design | Open components |

| Customization | Moderate | High |

Buying Advice & Selection Guidelines

Before choosing a compact substation, consider the following:

- Load Demand: Estimate peak and average loads to size the transformer and LV panel.

- Installation Environment: Choose enclosure protection (IP54/IP65) based on weather and dust exposure.

- Mobility: For temporary sites like construction, opt for transportable skid-mounted units.

- Cooling System: Dry-type is safer indoors, oil-immersed is cost-effective outdoors.

- Standards Compliance: Always select products certified under IEC/ISO standards for safety and performance.

For mission-critical sites, consult certified vendors and request a factory acceptance test (FAT) before delivery.

Common Use Cases

- Renewable Energy Farms: To connect solar/wind inverters to the grid.

- Smart Cities: For underground and space-limited power distribution.

- Data Centers: Provide high-reliability compact energy nodes.

- Construction Sites: Quick, movable power source during building stages.

Cited & Recommended Sources

- IEEE: Switchgear Standards Overview

- Wikipedia: Compact Substation

- IEEMA Reports on Power Distribution

- ABB Compact Substation Brochure

- Schneider Electric MV/LV Prefabricated Solutions

FAQ: Compact Substation Components

A: Yes. Most manufacturers offer oil-immersed or dry-type options, with custom voltages and cooling methods tailored to your load requirements.

A: With proper maintenance, a compact substation can operate efficiently for 20–30 years, depending on environmental factors and component quality.

A: Absolutely. With IP54+ enclosures, corrosion-resistant shells, and thermal management systems, they are designed for outdoor harsh conditions.

Compact substations represent a modern, efficient solution for today’s power distribution challenges. By integrating multiple electrical components into a single modular unit, they reduce installation time, improve safety, and support the evolution of smart grids and renewable infrastructure. Understanding the key components of these systems ensures informed decision-making whether you’re designing for an industrial plant or a utility-scale energy project.

For technical consulting or equipment sourcing, always engage with certified suppliers and refer to international standards such as IEC 62271 y IEEE documentation to ensure compliance and performance.