Oil transformers remain the backbone of electrical power systems worldwide, offering efficient voltage transformation and robust thermal management. They are essential for grid stability, industrial operations, and infrastructure development. But not all oil transformers are created equal—there are several types designed for specific roles, voltage levels, and cooling requirements. This in-depth guide will explore the main oil transformer types, their applications, market relevance, technical features, and expert selection tips.

What Is an Oil Transformer?

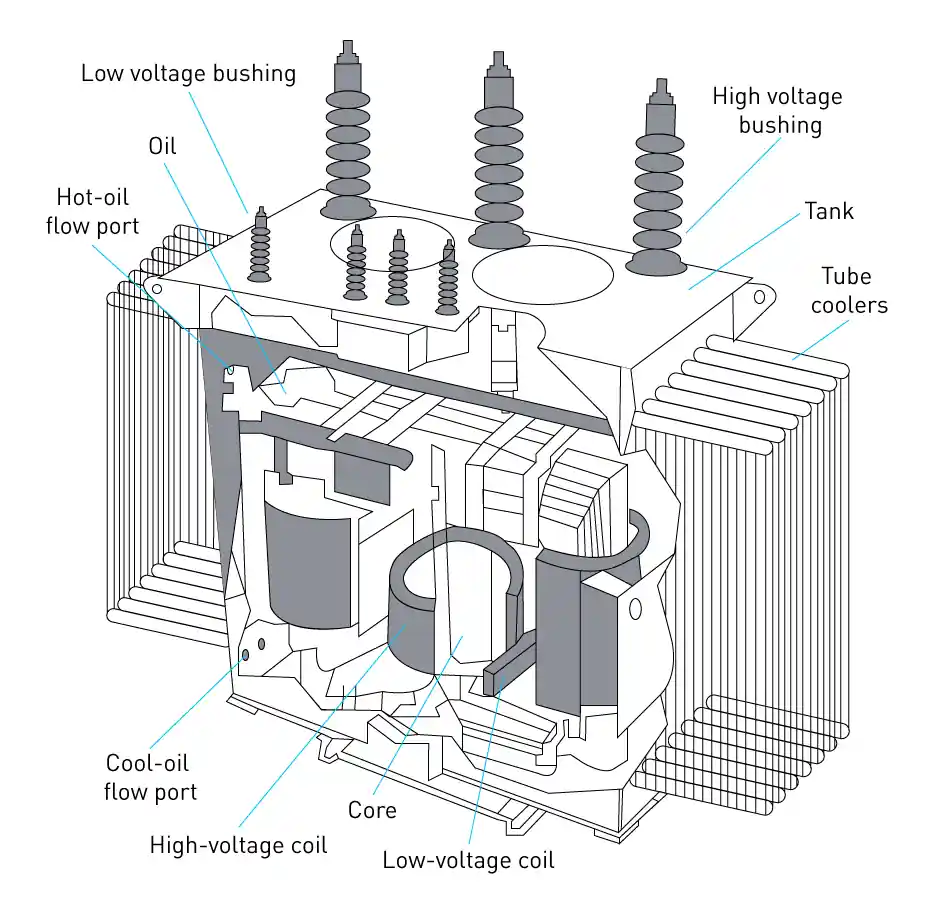

An oil transformer, also called an oil-immersed transformer, uses insulating oil (usually mineral oil or ester fluid) to cool and insulate the core and windings. The oil absorbs heat generated by electrical resistance and magnetic losses and transfers it to the tank walls or external radiators for dissipation.

Oil transformers are known for:

- High overload capacity

- Efficient heat dissipation

- Long service life with proper maintenance

Main Types of Oil Transformers

Depending on their design, cooling method, and application, oil transformers are classified into several types:

1. Distribution Oil Transformers

- Power Range: 25 kVA to 2500 kVA

- Voltage: Commonly 11 kV / 33 kV primary, 400 V secondary

- Application: Used in residential, commercial, and light industrial areas

- Features: Compact, low noise, often pole-mounted or pad-mounted

2. Power Oil Transformers

- Power Range: >2500 kVA (up to 500 MVA)

- Application: Substations, transmission lines, and power generation plants

- Typically custom-built with advanced cooling and protection systems

3. Hermetically Sealed Transformers

- No conservator tank; sealed to avoid contact with external air

- Reduces oxidation of oil, ideal for humid or polluted environments

4. Conservator Type Transformers

- Includes an oil expansion tank (conservator)

- Breathers and Buchholz relays enhance safety and monitoring

5. ONAN / ONAF Types

- ONAN (Oil Natural Air Natural): Natural convection cooling

- ONAF (Oil Natural Air Forced): Uses fans to improve cooling during high load

Application Fields

Oil transformers are used in:

- Utility Networks: Substations, rural electrification, and voltage step-down

- Industrial Plants: Powering motors, compressors, and production lines

- Renewable Energy: Voltage regulation in solar farms and wind power systems

- Infrastructure Projects: Airports, railway systems, water treatment plants

- Data Centers: For uninterrupted high-capacity power delivery

Market Trends and Background

With the global rise in electricity consumption and infrastructure investment, the demand for oil transformers remains strong. According to a report by MarketsandMarkets, the global transformer market is projected to exceed USD 90 billion by 2030, with oil-immersed models maintaining a dominant share due to their capacity and durability.

Leading manufacturers such as ABB, Schneider Electric, Siemens Energy, and PINEELE are innovating with:

- Biodegradable ester oils

- Smart grid integration via IoT sensors

- Low-loss core materials to meet energy efficiency standards

IEEE ja IEC guidelines, such as IEEE C57.12.00 ja IEC 60076, ensure standardized design, safety, and testing protocols.

Technical Parameters Overview (Typical Ranges)

| Tekniset tiedot | Value Range |

|---|---|

| Rated Capacity | 25 kVA to 500 MVA |

| Primary Voltage | 6.6 kV / 11 kV / 33 kV / 132 kV+ |

| Secondary Voltage | 400 V / 6.6 kV / 11 kV / custom |

| Cooling Methods | ONAN / ONAF / OFAF / OFWF |

| Insulation | Mineral oil / Synthetic / Ester oil |

| Impedance | Typically 4% – 10% |

| Efficiency | ≥98.5% at full load |

| Protection Class | IP23 to IP54 |

| Vector Group | Dyn11 / Yyn0 / others |

Oil Transformer vs. Dry Type Transformer

| Ominaisuus | Oil Transformer | Kuiva tyyppi muuntaja |

|---|---|---|

| Jäähdytysmenetelmä | Oil-based (better thermal capacity) | Air-based |

| Indoor/Outdoor | Suitable for outdoor | Preferred for indoor applications |

| Capacity Range | Higher (up to 1000 MVA) | Typically <10 MVA |

| Fire Risk | Requires containment and safety | Lower fire hazard |

| Maintenance Needs | Regular oil tests, breather checks | Minimal maintenance |

Choosing the Right Oil Transformer

When selecting an oil transformer, keep the following in mind:

- Load Profile: Understand peak vs. average load requirements.

- Installation Environment: Dust, humidity, and temperature affect cooling and insulation.

- Compliance: Ensure the unit adheres to IEC or IEEE standards.

- Efficiency Class: Opt for low-loss designs to reduce long-term energy costs.

- Accessories: Consider smart sensors, tap changers, temperature controllers, and surge arresters.

Frequently Asked Questions (FAQs)

A: Oil testing (DGA, moisture content, acidity) should be performed annually. Oil replacement depends on test results but typically every 5–10 years for high-load transformers.

A: While possible, it is not recommended due to fire risks. If necessary, they must be installed in a fire-rated room with ventilation and fire suppression.

A: With proper maintenance, oil transformers can last 25–40 years or more, depending on the operating environment and loading.

Oil Transformer guide types are diverse and tailored to suit various power distribution needs. From compact distribution transformers in urban areas to large-scale power transformers in substations, oil-immersed models offer exceptional reliability, thermal efficiency, and operational longevity.

Choosing the right type depends on your application’s load, environment, and regulatory requirements. By understanding the nuances of oil transformer classification and partnering with certified manufacturers, buyers can ensure a power solution that is both technically sound and economically sustainable.

If you’re planning an industrial upgrade, substation project, or infrastructure build-out, oil transformers remain a proven and adaptable choice in today’s energy ecosystem.

Get a printable version of this page as a PDF.