As the use of inverters becomes increasingly widespread in solar energy, industrial automation, UPS systems, and electric vehicles, the importance of selecting the right transformer guide cannot be overstated. Choosing a transformer that is incompatible with the inverter system can lead to overheating, harmonic distortion, inefficiency, or even system failure. So, which transformer is best for an inverter?

This article explores the technical considerations, transformer types, key specifications, and application-specific recommendations to help engineers, integrators, and buyers make informed decisions.

Understanding the Core Concept: Inverter and Transformer Relationship

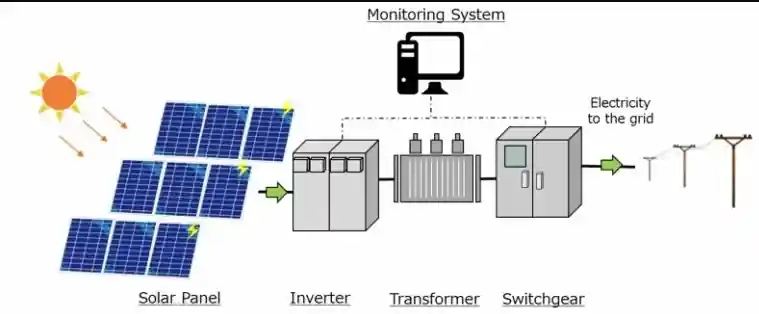

An inverter transforms direct current (DC) into alternating current (AC), typically using high-frequency switching techniques such as pulse-width modulation (PWM). A transformer paired with an inverter often performs voltage conversion (step-up or step-down) and galvanic isolation, ensuring safety and compatibility with downstream equipment.

Unlike grid-frequency transformers, inverter transformers operate at much higher frequencies (often 20 kHz to 100 kHz). This calls for specialized designs that prioritize thermal management, efficiency, és EMI (electromagnetic interference) suppression.

Common Applications for Inverter-Compatible Transformers

Transformers optimized for inverter use appear across various industries:

- Solar PV Systems: Converting 48V–600V DC to AC for grid integration.

- Uninterruptible Power Supplies (UPS): Managing battery-to-load conversion during outages.

- Electric Vehicle Chargers and Controllers: Enabling fast charging and motor control.

- HVAC and Motor Drives: Delivering variable-speed control in industrial settings.

- Telecom Power Systems: Stabilizing sensitive DC/AC interfaces.

Key Transformer Types for Inverter Applications

Different transformer designs offer specific benefits. Below are the most commonly used types:

1. High-Frequency Ferrite Core Transformers

- Used in switch-mode power supplies and compact inverters.

- Lightweight, efficient, and highly customizable.

- Ideal for solar micro-inverters and portable UPS systems.

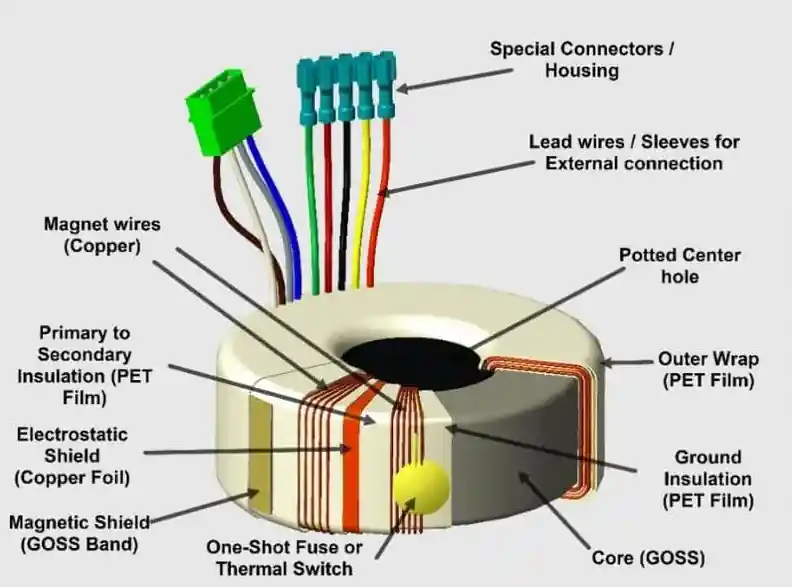

2. Toroidal Transformers

- Known for compact size, low leakage inductance, and quiet operation.

- High efficiency and low magnetic stray field.

- Suitable for audio systems, low-noise UPS, and residential inverters.

3. EI Core Transformers

- Traditional laminated steel core designs.

- Easier to manufacture and repair.

- Used in larger UPS and industrial inverters with moderate efficiency requirements.

4. Isolation Transformers

- Provide electrical separation between the input and output sides.

- Improve safety and noise immunity.

- Common in medical inverters and telecom systems.

Technical Parameters to Consider

Choosing the right transformer involves evaluating key specifications:

| Parameter | Importance in Inverter Use |

|---|---|

| Frequency Range | Must match high-frequency switching from inverter |

| Power Rating | Must exceed peak load requirements with safety margin |

| Voltage Ratio | Determines output voltage compatibility |

| Thermal Performance | Must handle heat from high-frequency operation |

| EMI Shielding | Prevents interference with other equipment |

| Insulation Class | Defines operational safety and thermal limits |

Market Trends and Design Advancements

With the rise in distributed energy systems and electrification, inverter transformers are evolving rapidly:

- Compact, high-density designs: Transformers are becoming smaller, lighter, and more efficient through ferrite or amorphous core usage.

- Integrated magnetics: Some inverter systems integrate the transformer within the power stage PCB to reduce form factor and cost.

- Smart monitoring: Sensors are now embedded to measure temperature, overload, and insulation breakdown.

- Green compliance: EcoDesign and RoHS regulations are pushing for high-efficiency, low-loss designs.

Manufacturers are investing heavily in R&D to meet the demands of fast-switching semiconductors like SiC and GaN, which require transformers with ultra-low leakage and high voltage isolation.

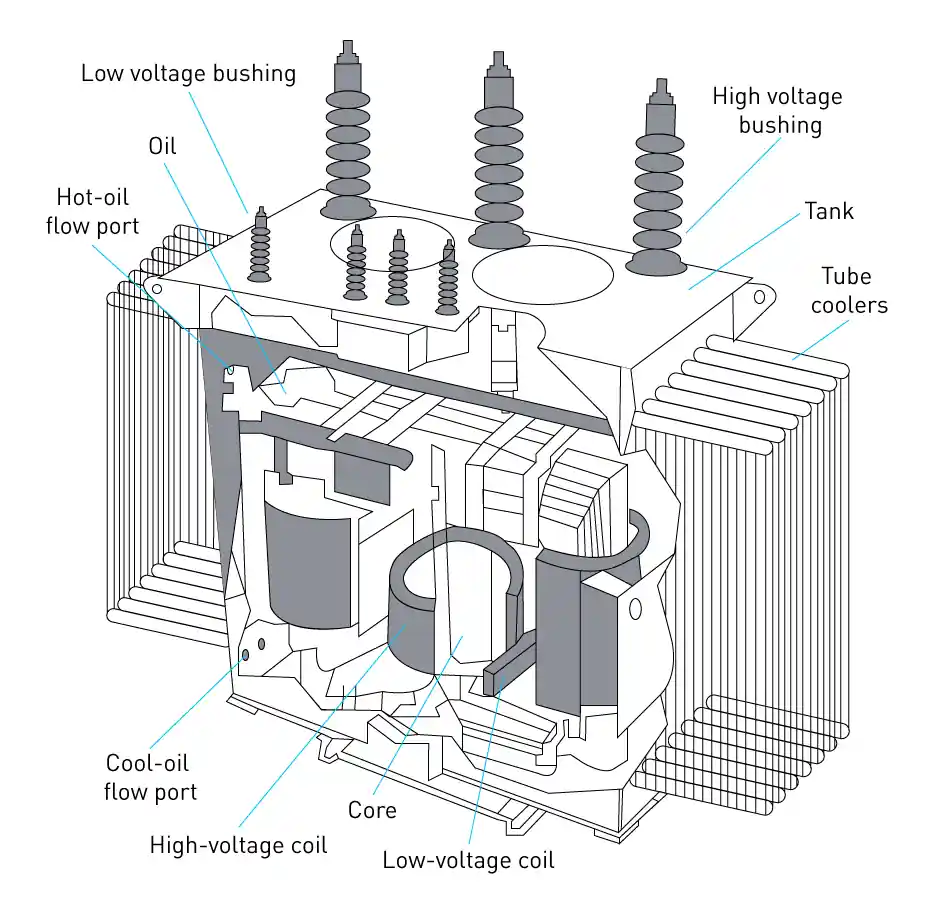

Oil-Type vs Dry-Type Transformers for Inverters

| Feature | Dry-Type Transformer | Olajba ágyazott transzformátor |

|---|---|---|

| Cooling Method | Air-cooled, convection | Oil-cooled, sealed tank |

| Safety | Higher fire resistance | Requires flameproof areas |

| Size and Noise | Compact but louder | Quieter but bulkier |

| Maintenance | Minimal | Periodic oil testing needed |

| Use Case | Indoor UPS, EVs, Solar | Outdoor industrial systems |

Verdict: For most inverter setups under 500 kW, dry-type or ferrite core transformers are preferred due to safety and efficiency. Oil-type units are used only in large outdoor or utility-scale projects.

Selection Guide: Choosing the Right Transformer

- Define Load Requirements

Understand both peak and continuous power levels. - Match Frequency

Verify that the transformer is rated for your inverter’s switching frequency. - Check Size and Mounting

Ensure it fits in your available enclosure or cabinet. - Consider Isolation

Use isolation transformers where safety or noise suppression is critical. - Prioritize Efficiency

High-efficiency units reduce long-term energy losses and heat buildup. - Ensure Compliance

Confirm certification with IEEE, IEC, or equivalent standards. - Ask for Custom Design if Needed

For high-performance or niche applications, work with OEMs to create custom windings, taps, or shielding.

Gyakran ismételt kérdések (GYIK)

A: Standard low-frequency transformers are not suitable for high-frequency inverter applications. They can overheat or introduce harmonic distortion. Always use transformers designed for inverter compatibility.

A: You risk overvoltage, overheating, low efficiency, and damage to both the transformer and the inverter. In some cases, improper grounding can even create safety hazards.

A: Toroidal transformers are more efficient and compact, ideal for sensitive applications. EI cores are more affordable and easier to manufacture but may suffer from higher losses and magnetic noise.

Következtetés

The best transformer for an inverter depends on application type, power level, frequency range, and environmental constraints. For residential and light commercial inverters, toroidal or high-frequency ferrite core transformers are ideal. For industrial systems, customized dry-type or laminated transformers with EMI suppression and proper insulation offer the best balance of performance and safety.

Whether you’re sourcing for solar inverters, battery storage systems, or motor drives, always prioritize transformers engineered specifically for inverter use. This ensures not only performance and reliability but also compliance with safety and efficiency standards that protect both people and equipment.