A 1 megawatt (MW) transformer is a critical piece of equipment used to step voltage up or down in medium- to high-power applications. From large commercial buildings to renewable energy systems and industrial plants, this size transformer serves as the backbone of efficient and stable electrical distribution.

But how much does a 1 MW transformer guide really cost? The answer isn’t as straightforward as a single price tag—it depends on the transformer’s type, configuration, brand, cooling method, voltage class, and many other factors. In this guide, we’ll unpack all the elements influencing cost and provide practical buying guidance.

Understanding the Basics: What is a 1 MW Transformer?

A 1 megawatt transformer typically refers to a transformer with a rated capacity of 1,000 kVA to 1,250 kVA (kilovolt-amperes), depending on power factor and application specifics. These transformers are designed to handle medium- or high-voltage loads and are used to either:

- Step down high-voltage electricity from the grid to usable levels for industrial or commercial use;

- Step up voltage from localized generation (e.g., solar or gas turbines) to grid levels.

Types of 1 MW transformers include:

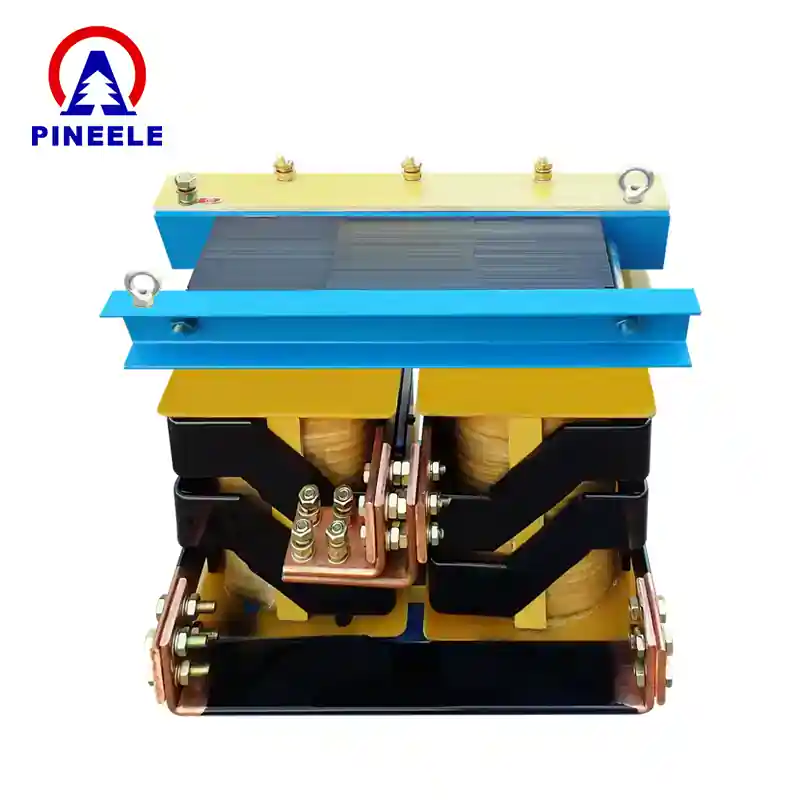

- Oil-immersed transformers

- Dry-type (cast resin) transformers

- Pad-mounted transformers

- Amorphous core transformers

Where Are 1 MW Transformers Used?

Transformers in the 1 MW range are commonly deployed in:

- Industrial Facilities: Supplying high-power machinery such as compressors, motors, furnaces, and conveyor systems.

- Renewable Energy Plants: Connecting solar farms and wind turbines to local or regional grids.

- Data Centers: Providing uninterrupted power to critical infrastructure.

- Commercial Real Estate: Supplying large office towers, shopping centers, or mixed-use developments.

- Hospitals and Airports: Powering complex systems that require high reliability and redundancy.

Transformer Cost: Price Range Overview

Here is a general cost breakdown based on real-world procurement data and manufacturer benchmarks.

| Transformer Type | Typical Price Range (USD) |

|---|---|

| Oil-immersed (ONAN) | $8,000 – $14,000 |

| Dry-type (cast resin) | $12,000 – $20,000 |

| Pad-mounted (enclosed) | $13,000 – $22,000 |

| Amorphous core (efficient) | $14,000 – $24,000 |

Note: These are base prices. Final delivered cost will vary depending on freight, taxes, protection features, and customization.

Technical Factors That Affect Cost

Several technical parameters can influence the final price of a 1 MW transformer:

1. Voltage Rating

Higher primary or secondary voltages (e.g., 33kV/11kV) require more insulation and larger clearances, increasing the cost.

2. Cooling Type

- Oil-immersed transformers (ONAN/ONAF) are less expensive per kVA.

- Dry-type transformers are safer in indoor or fire-prone areas but cost more.

3. Efficiency Class

Eco-efficient models (like amorphous core transformers) reduce core losses but come at a premium.

4. Core and Coil Design

- Cold-rolled grain-oriented (CRGO) steel is standard.

- Amorphous metal cores offer lower loss and better efficiency, but cost more.

5. Taps and Voltage Regulation

Transformers with on-load tap changers (OLTC) or fine voltage regulation capabilities add complexity and cost.

6. Enclosure and Mounting

Outdoor installations need weatherproof and dust-resistant enclosures (IP44/IP65), often increasing the price.

7. Testing and Compliance

Units conforming to standards such as IEEE C57, IEC 60076あるいは ISO 9001 generally cost more but offer guaranteed reliability.

Oil-Immersed vs Dry-Type: A Quick Comparison

| Feature | 油浸変圧器 | Dry-Type Transformer |

|---|---|---|

| Cooling Medium | Mineral or silicone oil | Air/natural convection |

| Installation | Outdoor preferred | Indoor or enclosed areas |

| Fire Risk | Higher (requires fire barrier) | Lower (self-extinguishing) |

| Maintenance | Periodic oil testing needed | Minimal maintenance |

| Cost per kVA | Lower | Higher |

| Efficiency | Higher | Slightly lower |

Market Trends and Global Demand

The global transformer market has seen strong growth due to rising electricity demand, industrialization in emerging markets, and the proliferation of renewable energy systems.

- Asia-Pacific remains the largest market, driven by grid upgrades in China and India.

- North America and Europe are investing in eco-design and smart grid-compatible transformers.

- Material and freight cost inflation in recent years has increased transformer prices by 30–50% in some regions.

Analysts forecast the global transformer market to exceed USD 90 billion by 2030, with the medium-power segment (like 1 MW units) seeing particularly high growth.

Buying Advice and Selection Guidelines

Purchasing a 1 MW transformer is a significant investment. Here’s how to approach the process:

- Determine Load Profile

Understand your maximum and average load demands, considering potential future expansion. - Evaluate Site Conditions

Indoor vs. outdoor installation, altitude, temperature, and seismic zone all influence specs. - Request Manufacturer Datasheets

Review technical documentation to compare loss levels, efficiency, and thermal performance. - Verify Standards Compliance

Ensure the product complies with relevant standards: IEEE, IEC, ANSI, or local utility regulations. - Compare Total Ownership Costs

Don’t just consider initial price—evaluate maintenance, downtime risk, and energy losses over the transformer’s lifetime. - Work with Trusted Suppliers

Choose manufacturers with proven track records in quality, warranty support, and spare parts availability.

Frequently Asked Questions (FAQ)

Yes. For mid-sized manufacturing plants with machinery loads and localized substations, a 1 MW transformer is typically ideal. However, actual sizing depends on real load analysis.

Generally no, unless the unit is enclosed in a weatherproof cabinet with proper ventilation. Most dry-types are designed for indoor environments.

Standard models may be ready in 4–8 weeks. Custom units with special configurations may take 10–16 weeks, depending on the manufacturer’s capacity and logistics.

Conclusion

The cost of a 1 MW transformer varies depending on multiple factors, but typically falls within the $8,000 to $24,000 range. When selecting a transformer, it’s important to consider both technical compatibility そして economic viability—not just the base price.

Transformers are long-term infrastructure assets. Making the right choice ensures operational reliability, safety, and energy efficiency. Consulting with experts, verifying compliance standards, and comparing supplier options are key to successful procurement.