Dry type transformers have become a cornerstone in modern power systems due to their superior safety, minimal maintenance, and eco-friendly characteristics. Unlike traditional oil-immersed transformers, dry type variants do not use liquid insulation, making them suitable for indoor and environmentally sensitive applications. This article explores the main types of dry type transformers, their applications, performance, and how to choose the right type for specific needs.

What is a Dry Type Transformer?

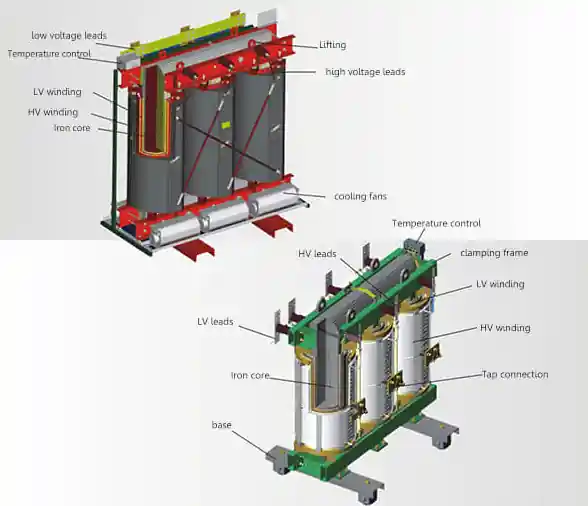

A dry type transformer is a transformer that uses air instead of oil for cooling and insulation. The windings and core are kept within a sealed enclosure and are cooled through natural air ventilation or forced air systems. These transformers are fire-resistant, safer in populated or enclosed environments, and preferred in many industrial and commercial sectors.

Main Types of Dry Type Transformers

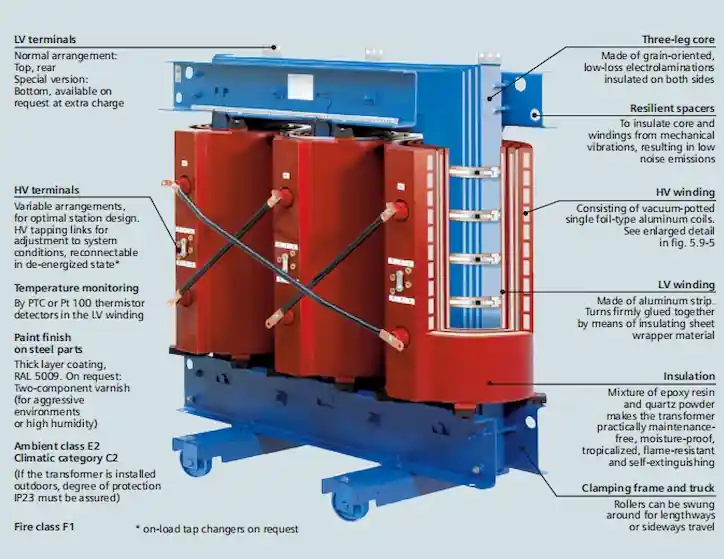

1. Cast Resin Transformer (CRT)

Cast resin transformers use epoxy resin to encapsulate windings, protecting them from moisture and contaminants.

- Best for: Humid or chemically aggressive environments.

- Advantages: High short-circuit strength, moisture resistance, no need for fireproof vaults.

2. Vacuum Pressure Impregnated (VPI) Transformer

VPI transformers are impregnated with varnish under vacuum and pressure, offering good insulation without full encapsulation.

- Best for: Industrial indoor applications with controlled conditions.

- Advantages: Lower cost than CRT, repairable coils, less weight.

3. Open Wound Transformer

This traditional design relies on open windings cooled by ambient air. They are gradually being phased out due to safety limitations.

- Best for: Small indoor installations with low risk.

- Advantages: Simple design, easy inspection and repair.

Applications of Dry Type Transformers

Dry type transformers are widely used in:

- High-rise buildings

- Hospitals and schools

- Metro stations and airports

- Wind and solar power systems

- Offshore drilling platforms

- Data centers and tech parks

As noted by the International Electrotechnical Commission (IEC) and IEEE, dry transformers are ideal for urban, fire-sensitive, or environmentally controlled spaces.

Industry Trends and EEAT Authority

According to Wikipedia’s Transformer entry, the demand for dry type transformers is rising due to safety regulations, urban expansion, and environmental concerns. Manufacturers like ABB, Schneider Electric, and Siemens continue to innovate in cast resin and smart dry transformer technologies.

The IEEMA (Indian Electrical & Electronics Manufacturers’ Association) highlights a 12% annual growth rate in dry type transformers in commercial and renewable sectors.

Technical Comparison

| Feature | Cast Resin (CRT) | VPI | Open Wound |

|---|---|---|---|

| Insulation | Epoxy resin | Varnish | Air |

| Cooling | AN / AF | AN / AF | AN |

| Moisture Resistance | Excellent | Moderate | Low |

| Repairability | Difficult | Easy | Easy |

| Cost | Higher | Moderate | Low |

Differences from Oil-Immersed Transformers

| Aspect | Dry Type | Oil-Immersed |

|---|---|---|

| Cooling Medium | Air | Mineral Oil |

| Fire Risk | Very Low | Moderate to High |

| Environmental Risk | Minimal | Potential leakage |

| Maintenance | Minimal | Regular oil checks |

| Installation | Indoors & outdoors | Mostly outdoors |

Buying Guide: How to Choose the Right Type?

- Environment: For humid or corrosive areas, go with CRT.

- Budget-sensitive projects: VPI transformers offer a balance between cost and performance.

- Compact indoor setups: Use dry type transformers with forced-air cooling and flame-retardant enclosures.

- Compliance: Always select transformers certified under IEC 60076-11 or IEEE C57.12.91 standards.

FAQs

A1: Initially yes, but they save money in the long term due to lower maintenance and safety infrastructure requirements.

A2: Yes, with proper enclosures (IP rated), dry type transformers can withstand outdoor conditions.

A3: Commercial buildings, hospitals, marine, wind power, and data centers all prefer them for their safety and compact size.

Dry type transformers represent the future of compact, safe, and efficient power distribution systems. As the demand for urban and sustainable energy infrastructure grows, these transformers will remain vital across industries.