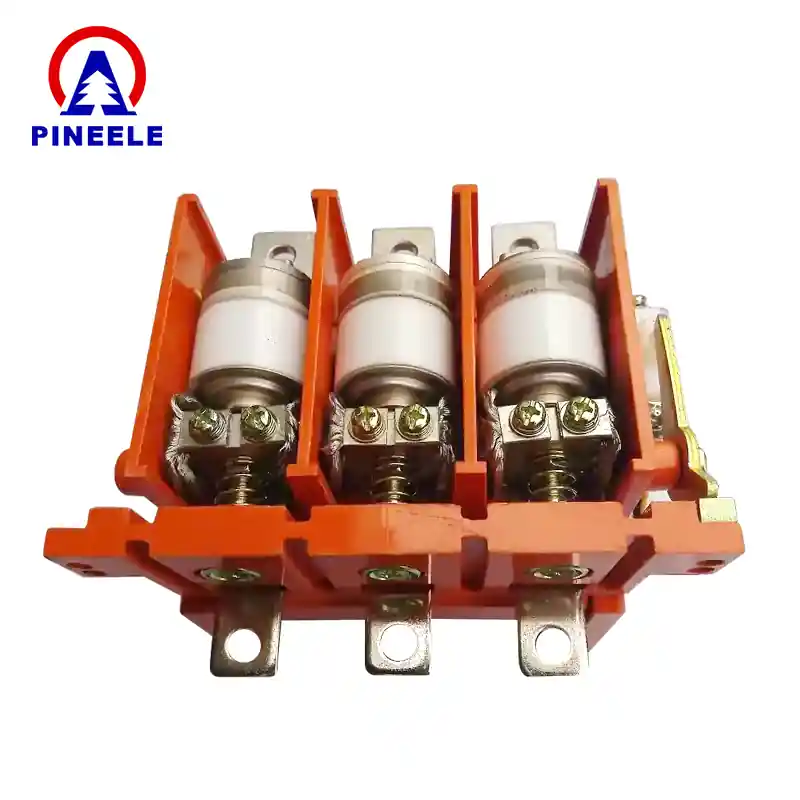

AC Vacuum Contactor

The AC Vacuum Contactor is a specialized switching device designed for controlling AC circuits in medium and high-voltage systems. Using vacuum as the arc extinguishing medium, it ensures safe, fast, and reliable switching with minimal wear and long service life. Ideal for applications in power distribution, industrial automation, and motor control, this contactor supports frequent operation and provides superior performance in harsh environments.

Key Features:

-

Vacuum arc-quenching technology for extended electrical life

-

Compact design with excellent insulation performance

-

High reliability for frequent switching operations

-

Suitable for motor starting, capacitor switching, and transformer control

-

Compliant with international standards (IEC/GB)

Applications:

-

Power substations

-

Industrial motor control

-

Capacitor banks

-

Railway and mining systems

-

Smart grid solutions

Introduction to the AC Vacuum Contactor

The AC Vacuum Contactor is a high-performance electrical switching device designed for controlling AC circuits, particularly in medium-voltage applications. Unlike traditional air contactors, the vacuum contactor utilizes a vacuum interrupter to extinguish the arc during the switching process. This results in significantly reduced contact erosion, improved safety, and longer operational life.

Thanks to its compact design, high switching frequency, and excellent arc-quenching capability, the AC Vacuum Contactor is widely used in industrial and utility sectors. Whether for motor control, capacitor bank switching, transformer switching, or reactive power compensation systems, this device plays a vital role in ensuring electrical system reliability and operational efficiency.

The use of vacuum technology ensures minimal maintenance, quiet operation, and outstanding electrical insulation. As industries increasingly demand safer and more efficient control solutions, the AC Vacuum Contactor has become an essential component in modern power distribution and control networks.

Key Performance Features

- Vacuum Arc Extinguishing: Ensures safe and efficient interruption of electric current with minimal contact wear.

- High Frequency Operation: Suitable for frequent switching cycles without compromising performance.

- Compact Design: Space-saving structure ideal for modern, dense electrical panels.

- Extended Service Life: Durable components and vacuum chamber technology provide a long operational lifespan.

Technical Specifications

| Parameter | Specification |

|---|---|

| Rated Voltage | AC 7.2kV / 12kV |

| Rated Current | 125A / 250A / 400A / 630A |

| Mechanical Life | 1 million operations |

| Electrical Life | Over 100,000 operations |

| Rated Operating Frequency | 50Hz / 60Hz |

| Control Voltage | AC/DC 110V / 220V |

Installation & Maintenance Tips

For optimal performance and safety, please consider the following installation and maintenance guidelines:

- Installation Environment: Ensure the contactor is installed in a dry, dust-free, and vibration-free enclosure.

- Wiring: Use standard-compliant cables and connectors to ensure secure and heat-resistant joints.

- Ventilation: Provide sufficient airflow to prevent overheating during high-duty cycles.

- Maintenance: Periodically check for signs of wear, thermal discoloration, or contact bounce. Clean and test bi-annually.

Why Choose Our Contactors

Our AC Vacuum Contactors offer unmatched performance and reliability compared to conventional models:

- Superior Quality: Built with premium vacuum interrupters and high-grade insulation materials.

- Certified Safety: Fully compliant with IEC, GB, and ANSI standards.

- Competitive Pricing: Direct-from-manufacturer pricing ensures cost-effectiveness without compromising quality.

- Dedicated Support: Professional technical assistance and responsive customer service available worldwide.