Electrical Insulators – Ensuring Safe and Efficient Power Transmission

Electrical insulators are critical components in power transmission, preventing unwanted current flow and ensuring safe electricity delivery. Made from high-resistance materials like porcelain, glass, or polymers, they protect systems from short circuits, leaks, and electrical hazards across grids, substations, and renewable energy networks.

Key Types of Electrical Insulators

- Porcelain Insulators: Durable, high-voltage resistant.

- Glass Insulators: Weather-resistant for versatile applications.

- Polymer Insulators: Lightweight, ideal for harsh environments.

- Composite Insulators: Engineered for extreme mechanical/electrical stress.

Applications of Electrical Insulators

- Transmission Lines: Prevent current leakage on towers.

- Substations: Isolate equipment to avoid faults.

- Renewable Energy: Secure connections in solar/wind systems.

- Distribution Networks: Safeguard end-user power delivery.

Why Choose Quality Electrical Insulators?

- Safety: Block dangerous current flow.

- Reliability: Maintain performance in extreme conditions.

- Longevity: Resist corrosion, UV, and pollution.

Upgrade Your Power Systems

Our premium electrical insulators combine advanced materials and precision engineering for unmatched safety and efficiency. Trusted in high-voltage transmission, renewable projects, and industrial grids—contact us today for tailored solutions.

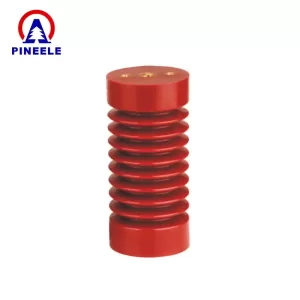

Composite Insulators: Power Grid Innovation

Superior Performance in Extreme ConditionsComposite Insulators combine silicone rubber, fiberglass cores, and metal fittings to outperform traditional porcelain insulators. These advanced components withstand temperatures from -50°C to +150°C while resisting UV degradation, salt fog, and industrial pollution.

Key Technical Advantages

• 50% lighter than porcelain insulators

• 1200kV maximum system voltage capacity

• Hydrophobic surface prevents moisture buildup

• Vibration damping for wind-prone areas

Critical Industry Applications

Composite Insulators enable safer power transmission in:

HVDC Networks: Reduce corona discharge in 800kV+ systems

Offshore Wind Farms: Resist salt corrosion in marine environments

Railway Electrification: Maintain stability under high-speed vibrations

Smart Grids: Compatible with IoT monitoring systems

Certified Reliability Standards

All Composite Insulators meet IEC 61109 and ANSI C29 specifications, with optional leakage current sensors for predictive maintenance. Third-party testing verifies 25+ year lifespans under IEC 62217 stress conditions.

Future-Ready Insulation Technology

Next-gen Composite Insulators integrate nano-coated silicone sheds for self-cleaning and 3D-printed fittings that reduce installation time by 40%. Sustainable variants use recycled polymer materials without compromising dielectric strength.

Understanding Electrical Insulators: Key Components for Safe Power Systems

Electrical insulators play a crucial role in power systems by ensuring that electricity flows safely and efficiently. These components are designed to prevent unintended flow of electricity, isolating electrical conductors from ground and other conductive materials. In this section, we will explore the key aspects of electrical insulators, including their types, applications, and maintenance, to highlight their importance in maintaining a safe and reliable power network.

What is an Electrical Insulator? A Comprehensive Overview

An electrical insulator is a material or device that resists the flow of electrical current. It serves to protect power systems from electrical faults and prevent unintended contact with live electrical parts. Insulators are commonly used in power transmission lines, transformers, and electrical equipment to keep electrical currents confined to their designated paths. In this section, we dive deep into the fundamental properties and functions of electrical insulators.

Types of Electrical Insulators: Materials and Applications

Electrical insulators come in various types, each designed to meet specific needs in power transmission and distribution systems. The materials used for electrical insulators include glass, porcelain, and composite materials, each with its unique set of advantages. We will discuss the most common types of insulators and where they are used in the electrical grid and other industries.

Importance of Electrical Insulators in High-Voltage Systems

High-voltage systems rely heavily on electrical insulators to maintain safety and efficiency. These systems require insulators that can withstand the mechanical and electrical stresses that come with high voltage transmission. In this section, we examine why electrical insulators are especially important in high-voltage applications and how they help prevent equipment damage and electrical hazards.

How Electrical Insulators Prevent Electrical Accidents

Electrical accidents, such as electrical shocks and short circuits, can lead to severe damage or even fatalities. Electrical insulators are designed to prevent these accidents by isolating electrical conductors and controlling the flow of electricity. We will explore how insulators prevent electrical accidents and ensure the safety of both electrical infrastructure and people working near electrical systems.

Choosing the Right Electrical Insulator for Your System

Choosing the right electrical insulator depends on factors such as voltage level, environmental conditions, and the type of system in which it will be used. This section provides valuable insights on how to select the best insulator for different applications, ensuring optimal performance and safety for your electrical systems.

Common Applications of Electrical Insulators in Power Networks

Electrical insulators are used in a wide range of applications within power networks, including transmission lines, substations, and transformers. In this section, we discuss the most common uses of electrical insulators, highlighting their role in both overhead and underground power transmission systems.

Maintenance and Inspection Tips for Electrical Insulators

Proper maintenance and regular inspections of electrical insulators are essential to ensure their longevity and functionality. This section provides key tips on how to maintain and inspect electrical insulators, including identifying potential issues such as wear and degradation due to environmental factors or electrical stresses.

Why Electrical Insulators are Crucial for Power Line Safety

Power lines carry high-voltage electricity over long distances, and electrical insulators are essential for ensuring that these lines remain safe and functional. This section highlights the role of insulators in power line safety and how they help prevent electrical outages, fires, and accidents.

Electrical Insulator Manufacturing: Quality Standards and Certifications

The quality of electrical insulators directly affects the performance and safety of electrical systems. In this section, we take a closer look at the manufacturing process of electrical insulators, including the quality standards and certifications that ensure these components meet the highest levels of performance and safety.

Future Trends in Electrical Insulator Technology

As the demand for more efficient and reliable power systems grows, so too does the need for advanced electrical insulators. In this section, we explore the latest innovations in electrical insulator technology, including new materials, design improvements, and developments in smart insulator technologies that monitor performance and enhance safety.