Dry type transformers are the backbone of modern electrical distribution, powering industrial plants, commercial buildings, and renewable energy projects. Unlike oil-immersed transformers, they use air for cooling, offering safety, eco-friendliness, and low maintenance. Selecting the right manufacturer is critical to ensure your transformer delivers on quality, safety, and durability. This guide covers what dry type transformers are, why the manufacturer matters, top global suppliers in 2025, and how to choose the best one for your needs.

What Is a Dry Type Transformer?

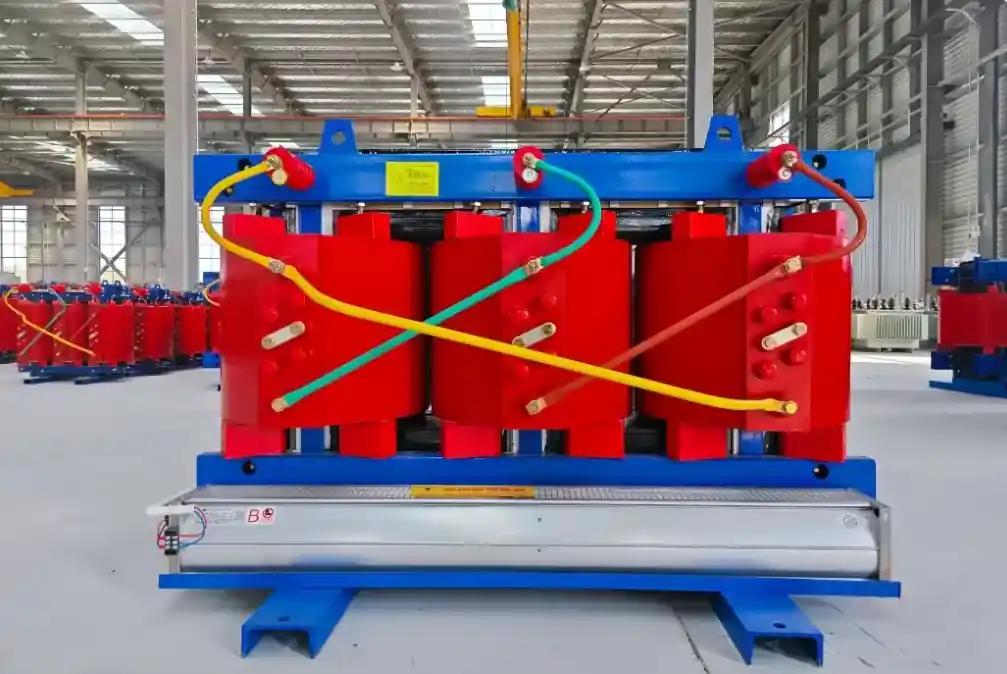

A dry type transformer uses air—rather than oil—for cooling and is typically insulated with resin. Known for fire resistance, environmental benefits, and minimal upkeep, these transformers suit a variety of settings, including:

- Shopping centers

- Hospitals

- Substations

- Data centers

- Renewable energy installations

“Dry type transformers excel in enclosed spaces due to their self-extinguishing properties and compact design.”

— IEEE Standards Association

Why the Manufacturer Matters

The quality of a dry type transformer hinges on the manufacturer. A reputable supplier ensures:

- Quality Assurance: Compliance with rigorous testing standards like IEC and IEEE.

- Material Excellence: High-grade, compliant components for reliability.

- After-Sales Support: Robust warranties and technical assistance.

- Customization: Tailored designs for specific kVA ratings, enclosures, and voltage needs.

Choosing wisely guarantees long-term performance and safety for your electrical system.

Top Dry Type Transformer Manufacturers in 2025

Here’s a list of leading manufacturers renowned for expertise, innovation, and reliability:

1. PINEELE (China)

PINEELE is a fast-growing Chinese supplier excelling in resin-cast and amorphous core dry type transformers, plus custom medium-voltage solutions.

- Key Strengths:

- Meets IEC60076 and ANSI/IEEE standards.

- In-house R&D and testing labs.

- Exports to over 30 countries.

- Offers OEM/ODM services.

2. Siemens Energy (Germany)

Siemens Energy, a global leader, provides dry type transformers for smart grids and industrial use.

- Standouts:

- Superior energy efficiency.

- Exceptional thermal performance.

- Trusted in healthcare, rail, and marine sectors.

“Siemens designs transformers to support decentralized renewable energy grids.”

— Siemens White Paper, 2024

3. ABB (Switzerland)

ABB is celebrated for its advanced insulation and eco-friendly dry type transformers.

- Highlights:

- Built for high-altitude environments.

- Low electromagnetic interference.

- ISO 9001 and ISO 14001 certified production.

4. Schneider Electric (France)

Schneider Electric offers cast resin transformers for urban and critical infrastructure projects.

- Advantages:

- Minimal partial discharge.

- Enhanced fire resistance.

- Supports remote monitoring.

How to Choose the Right Manufacturer

Selecting a manufacturer requires evaluating these key factors:

| Criteria | Why It’s Essential |

|---|---|

| Certifications | Confirms adherence to IEC, IEEE, and ISO standards for safety and quality. |

| Production Capacity | Ensures ability to meet your voltage, power, and scale requirements. |

| R&D and Testing | Validates customization and performance under real-world conditions. |

| Lead Time | Guarantees delivery aligns with your project timeline. |

| Technical Support | Provides pre- and post-sale assistance, including installation guidance. |

Prioritizing these ensures a manufacturer matches your project’s technical and logistical needs.

Applications of Dry Type Transformers

Dry type transformers are versatile, supporting:

- Industrial Facilities: Drives heavy machinery and production lines.

- Hospitals & Commercial Spaces: Delivers reliable power for critical systems.

- Solar & Wind Farms: Integrates renewable energy into grids.

- Railway Substations: Powers transportation networks.

- Data Centers: Ensures stable electricity for sensitive equipment.

“Dry transformers are ideal where fire safety and noise reduction are priorities.”

— Wikipedia: Dry-Type Transformer

Frequently Asked Questions (FAQs)

A: With proper maintenance, expect 25-30 years of service.

A: They may cost more initially but save money long-term with lower maintenance and safety benefits.

A: Yes, with IP-rated enclosures, they’re suitable for outdoor applications.