In the field of electrical engineering and power distribution, the distinction between MV (Medium Voltage) and LV (Low Voltage) is fundamental. These classifications determine how electrical energy is transmitted, transformed, and distributed from power plants to end users.

But what exactly do MV and LV represent? How do they differ in application, design, and technical characteristics?

This article provides a detailed breakdown of MV vs LV, helping engineers, facility managers, and infrastructure planners make informed decisions.

Core Definitions: What is MV and LV?

Medium Voltage (MV):

Typically refers to the voltage range between 1kV and 36kV (some standards extend this up to 72.5kV). MV is used to transport electricity over medium distances—usually from substations to large commercial or industrial users, or between transformers and local distribution points.

Low Voltage (LV):

Encompasses voltages below 1000V AC or 1500V DC, commonly used for residential, commercial, and light industrial consumption. LV is the final stage of the distribution system that directly supplies power to end users.

Applications: Where MV and LV Are Used

| Voltage Level | Primary Applications |

|---|---|

| MV (1kV–36kV) | – Industrial manufacturing plants – Grid-connected renewable energy – Utility substations – Large commercial complexes |

| LV (<1000V) | – Residential buildings – Offices and retail – Schools and hospitals – Data centers, IT facilities |

MV systems are more complex, require trained handling, and are typically installed in environments where higher power capacity and longer transmission are needed. LV systems are safer and more commonly encountered by general consumers.

Market Trends and Technical Evolution

Global demand for reliable power distribution has surged, particularly in developing economies and urban expansion zones. According to the International Energy Agency (IEA), the push toward decentralized grids and smart power systems is driving rapid investment in both MV and LV infrastructure.

Leading manufacturers like ABB, Schneider Electric, and Siemens have introduced modular solutions that integrate MV and LV systems within compact substations—enhancing deployment speed and operational efficiency.

Smart LV panels with IoT integration and MV switchgear with arc-flash protection are becoming standard in critical infrastructure projects.

Technical Parameters: MV vs LV Comparison Table

| Feature | Medium Voltage (MV) | Low Voltage (LV) |

|---|---|---|

| Voltage Range | 1kV to 36kV (up to 72.5kV in some standards) | Up to 1000V AC / 1500V DC |

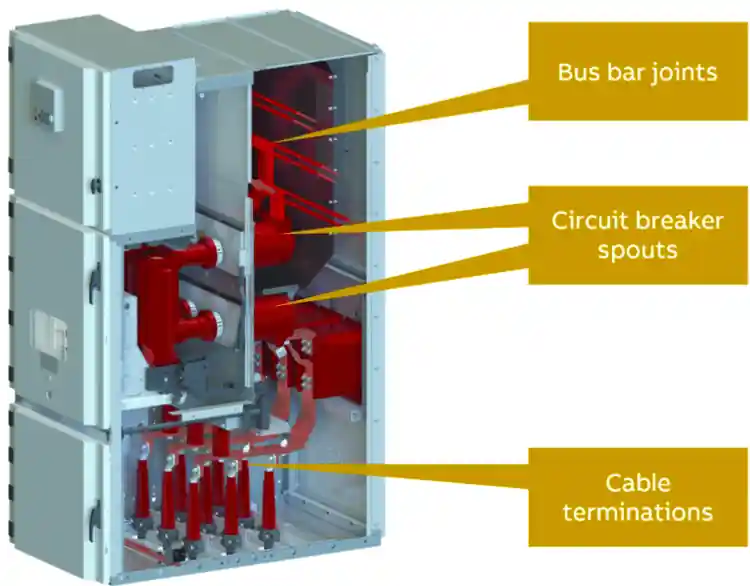

| Common Equipment | Switchgear, ring main units (RMUs), transformers | Distribution boards, MCCBs, MCBs |

| Insulation | SF6, vacuum, air-insulated | Mostly air-insulated |

| Applications | Transmission & industrial distribution | Direct power supply to end users |

| Maintenance | Requires trained personnel | Less complex, often managed by electricians |

| Installation | Indoor/Outdoor, larger footprint | Indoor, compact and modular options available |

Key Differences at a Glance

- Safety: LV is safer to handle, while MV requires arc-flash protection and safety protocols.

- Complexity: MV systems require more specialized components and installation design.

- Cost: MV equipment and installation are generally more expensive due to insulation and control systems.

- Power Capacity: MV systems can transmit higher power over longer distances efficiently.

Buying and Design Considerations

When designing or purchasing electrical distribution systems:

- Choose MV systems when dealing with high-power requirements (e.g., industrial parks, utility substations).

- Opt for LV systems for localized, low-demand environments (e.g., residential areas, small offices).

- Ensure all components conform to relevant standards such as IEC 60038, IEC 62271, or IEEE C37.

Leading vendors like PINEELE, ABB, and Schneider Electric offer modular MV-LV integrated solutions that are compact, efficient, and fully certified.

FAQ: MV vs LV

A: Yes. Compact substations often integrate MV input, step-down transformers, and LV output in a single unit. These are ideal for space-constrained industrial or commercial environments.

A: It depends on your total load (kW/kVA), distance from the utility connection point, and safety regulations. MV is used when power needs exceed 250kW or distances are long.

A: MV systems require grounding, arc-flash protection, isolation procedures, and routine testing by certified professionals.

Understanding the differences between MV and LV is essential for anyone involved in power distribution planning or facility management. MV systems provide efficient bulk power transmission over distances, while LV systems bring electricity to the final user in a safe and manageable format.

As urban infrastructure evolves and energy demand increases, both MV and LV will remain critical to the design of modern electrical guide networks. Selecting the right solution based on application, scale, and compliance ensures operational success and long-term safety.